The fundamental thing about Lean that you should know before diving any further into this article is:

There is no one-way to carry out Lean. Moreover, there is no way to carry it out without doing the necessary groundwork.

Now that that has been cleared, let us dive straight into the most important question. Why Lean deployment? The most common answer I hear during my client engagements is, “to get rid of non-value-added time and effort.”

Here is a look at what the practical implication of Lean is: Once, in a company, I could help an operator achieve a production of 500 pieces an hour. This was previously 250 pieces an hour. What was the change? I put single piece flow to work to achieve this feat. I asked, “How do you feel after achieving this feat?”. She replied, “I am happy that I could achieve this number and still not feel tired”.

The 3 Components of Successful Lean Deployment:

The goal of Lean is to give a company, its workers, and customers a “sense of achievement”. All 3 should draw value from its deployment. Here’s how you can do just that:

- Align Lean implementation with the ‘big picture’ – Lean should be considered to achieve a company’s long-term vision and objectives. If this disappears, its deployment becomes ‘program of the month’.

- Recognize the behaviours essential to the Lean journey – If a company tries to carry it out without considering what behaviour makes it click, it is preparing to fail. As a leader or a manager, you should first diagnose the current behaviours. After a careful analysis, set up practices to streamline these behaviours.

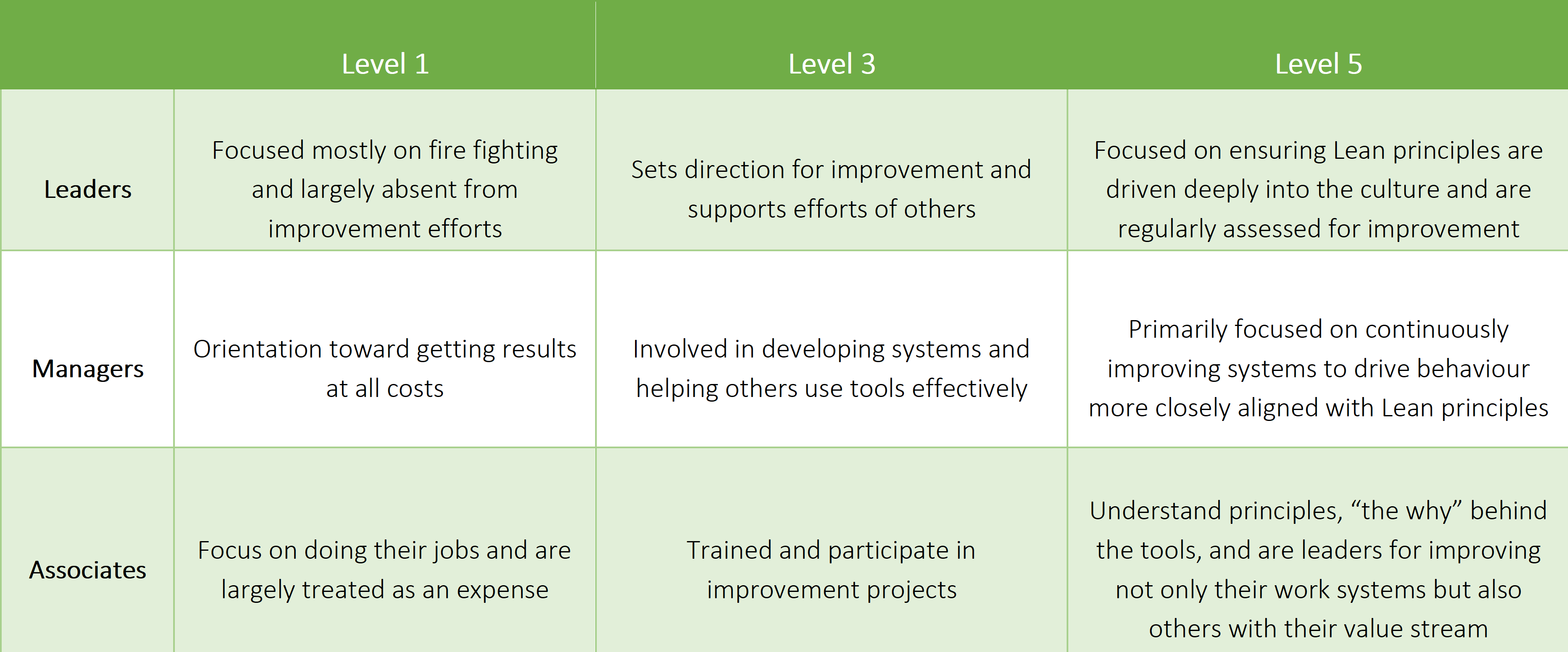

- A simple behaviour scale from the ‘Shingo behaviour assessment scale’ is useful (as shown in the table below). Hypothetically, if a company’s employees are at Level 1 (Leaders included), do not expect results that align with Level 5! Hence, consider it lucky if you can achieve great results at level 1! If you recognize the current state as Level 1, strive to reach level 5 simultaneously, as you apply basic principles of Lean to solve problems.

Shingo scale – skills assessment

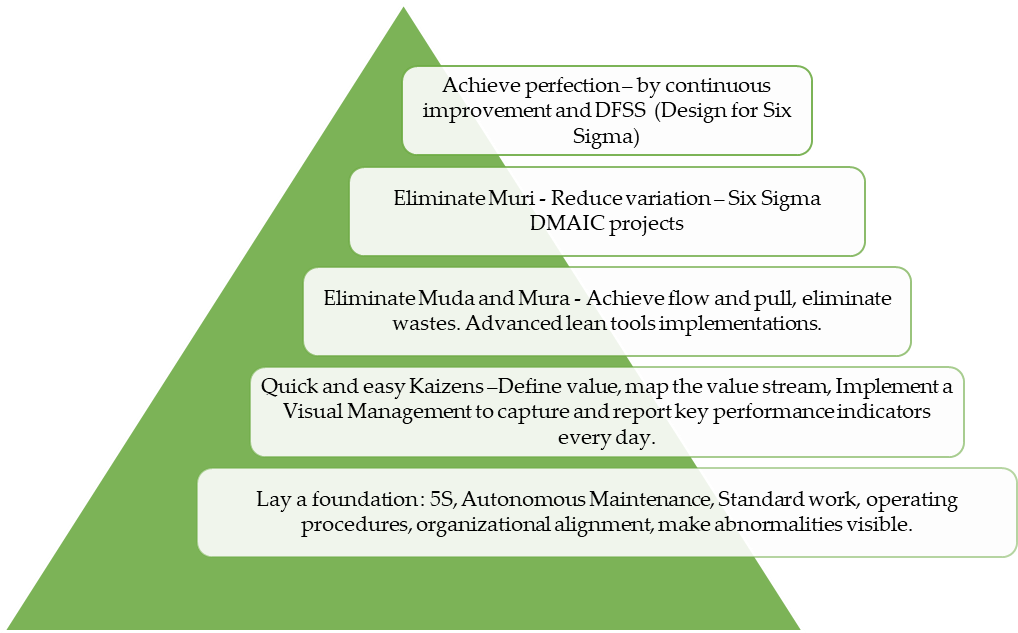

To implement Lean, you must first establish a good foundation in place – such as 5S, Autonomous Maintenance, Standard work, SOP’s (Standard Operating Procedures), and a balanced scorecard. With a good foundation, it is easy to identify and accomplish quick and simple Kaizens. After that, you must execute these kaizens to drive a culture of continuous improvement.

For the uninitiated, Kaizen is a Japanese term, meaning ‘change for better’. A sense of accomplishment is necessary to implement other Lean practices. To achieve the fifth principle ‘Perfection’, a roadmap is a must. It may take years to reach there!

Unfortunately, many leaders seek ‘Perfection’ as the starting point. However, Lean implementation is about the journey to achieve ‘perfection’, and not starting with one. If you are already perfect, you do not need to implement it – you are already doing great! So, just sustain what you are doing. Take a look at the pyramid which can guide your Lean implementation journey.

Lean Implementation Pyramid