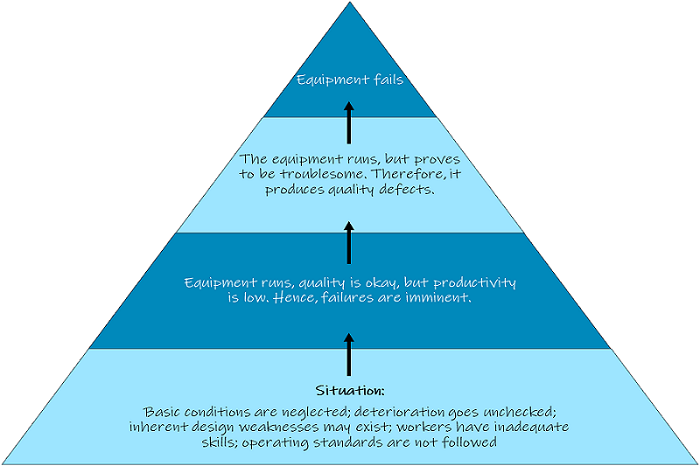

The Lean tool Total Productive Maintenance (TPM) has 8 pillars, which have been discussed at length below. To understand TPM, consider the following situation: A machine doesn’t usually break down all of a sudden. When an abnormality in it goes unchecked, it then results in a breakdown. Consequently, Total Productive Maintenance focuses on preventing such situations. The figure below shows how an abnormality progresses towards machine breakdown:

Figure 1: An abnormality leading to machine breakdown, with a result of equipment failure.

Total Productive Maintenance is a maintenance program concept. It brings the focus of maintenance into minimizing downtime and increasing equipment use. Furthermore, traditional TPM has 8 pillars. 5S is the first step. It provides the necessary foundation to achieve a successful implementation of TPM. Factories show that firstly, machines typically produce products only 60% of the time. Secondly, about 20% of the downtime is scheduled for lunch, breaks, and maintenance. Lastly, the remaining 20% is unscheduled due to machine breakdown setup time, parts shortages, and absenteeism.

Total Productive Maintenance can almost completely remove the unscheduled downtime. Additionally, the management initiatives can attack scheduled downtime. When a machine is running at near capacity, variation in parts or machine processing times can increase queue times by up to 20 times. While TPM is not the goal, it is the means to achieve zero breakdowns.

Pillars of Total Productive Maintenance

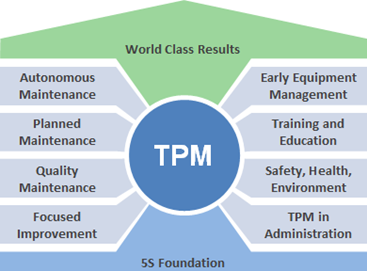

Total Productive Maintenance has 8 pillars, as shown below. Most importantly, the pillars ‘autonomous maintenance’ and ‘planned maintenance’ have a significant impact on unscheduled machine downtime.

Pillars of TPM

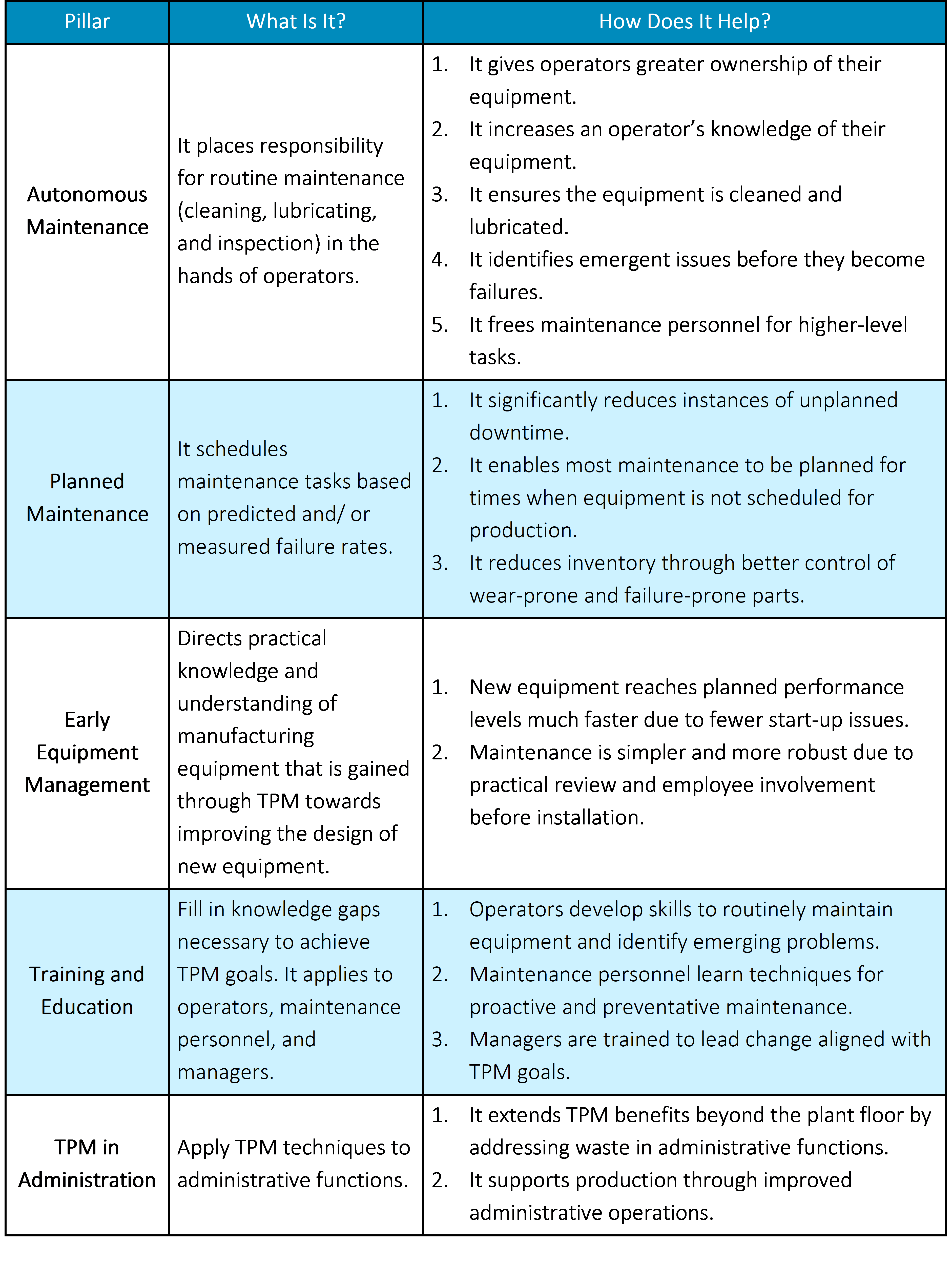

The table below explains how various pillars in TPM help overcome 6 big losses. It’s an important step in the upkeep of machines. Additionally, it emphasizes an operator’s involvement in the maintenance of machines.

Table 1: Pillars of TPM and How they Help

Total Productive Maintenance Implementation Strategy

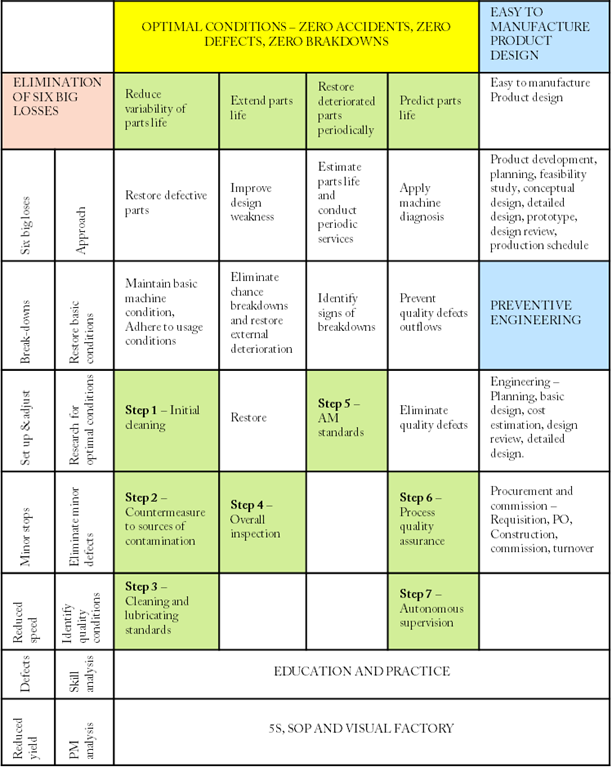

The table below provides an outline of TPM deployment in a company:

Table 2: A TPM Implementation Roadmap