Quick Change Over (QCO), also known as Single-Minute Exchange of Die (SMED), is a manufacturing Lean tool used to cast products. Single-minute is the reduction of changeover time to a ‘single-minute value’ (less than10 minutes). Additionally, QCO primarily comprises 3 steps, which we shall explore in this article. Is it applicable in services? No – at least not in the same way that it’s applicable in manufacturing. Take a look at what QCO consists of:

Figure 1: Changeover’s definition illustrated

Quick changeover is essential in companies that produce more than one product. Changeover is required from the settings of the previous product to that of the new product. Therefore, the changeover time is the time between the ‘LAST GOOD PART’ of the previous product to the ‘FIRST GOOD PART’ of the new product.

In my experience, several companies don’t even track and report changeover time – let alone improving it! Why? It’s because it is not considered as being non-value-added! It is part of the production time. Lack of lean knowledge is the reason! This needs to change. Here’s how you can do it:

Steps to implement QCO

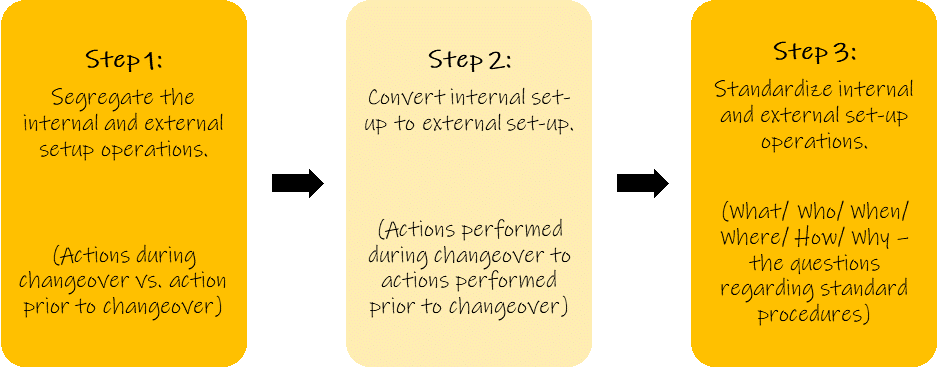

There are 3 steps to expedite quick changeover time in a factory:

Figure 2: Steps to implement QCO

Step 1 of Quick Changeover:

- You must segregate internal set-up and external set-up activities.

- Internal setup activities require the shutting down of a machine for a changeover. In other words, you can’t run any orders while the setup activity is taking place. Therefore, this is done while a process is idle.

- On the other hand, external steps are carried out while the process is operating. To clarify, external set-up operations do not impact the changeover time. In this step, you must first capture the ‘current state’ and the various tasks that take place during a changeover. After that, you need to classify them under internal and external set-up activities.

Step 2 of Quick Changeover:

- Once you segregate internal set-up and external set-up tasks, brainstorm with the team to convert internal set-ups into external set-ups.

- Convert as many actions as you can into external set-up tasks. Following this, carry them out before the changeover. You will note a significant decrease in changeover time by doing this. Make sure you carry your plan out on paper first.

Step 3 of Quick Changeover:

- In this stage, make sure you carry out a pilot.

- For this pilot, you must design new tools, jigs, and fixtures as per your requirement.

- Following the pilot run, refine the design if necessary.

- Lastly, standardize the new method of changeover. After that, continue to record and make modifications as and when required.