Poka-Yoke refers to the best system of mistake-proofing. It has 3 levels:

- Firstly, there should be an elimination of spills, leaks, and losses at the source. Alternatively, it could also assist in the prevention of a mistake.

- Secondly, the detection of a loss or mistake as it occurs is crucial. Therefore, it allows correction before it becomes a problem.

- Lastly, prevention is salient. This refers to the detection of a loss or mistake after it has occurred. Hence, it occurs just in time before it blows up into a major issue. However, this is the least effective level.

What is the difference between an error and a defect?

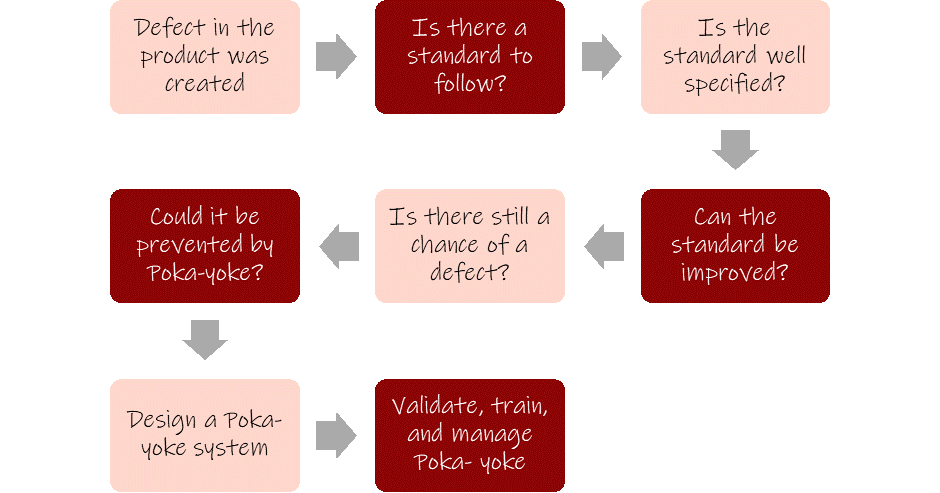

The difference between an error and a defect is pretty straightforward. The former is the cause, while the latter is the effect. Defect refers to the deviation from a standard. Therefore, it is the result of

something. The flowchart below explains the steps to develop a Poka-Yoke system. It elaborates on your need for a Poka-Yoke system in your workplace:

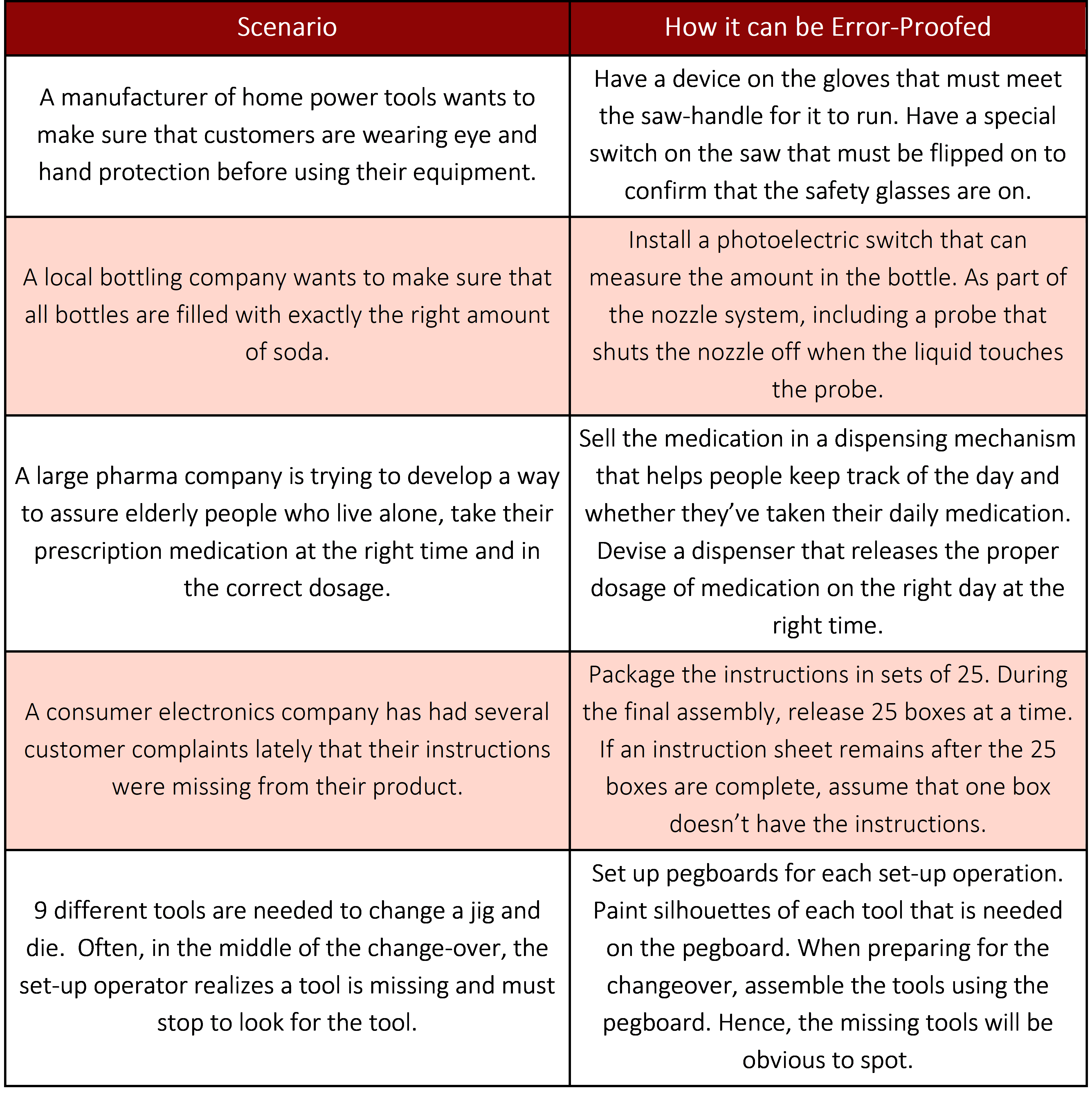

Here are some examples of Poka-Yoke system implementation in various scenarios. However, keep in mind that you will need to create examples for your specific work area. Your way of working will improve with each attempt!