The ‘standardize’ step is extremely important. This is because it works toward ensuring that the first 3 Ss (‘sort’, ‘set in order’, and ‘shine’) become an integral part of a company’s culture! To universally apply good practice in every part of an organization is harder than putting just one in place. Therefore, standardization is crucial.

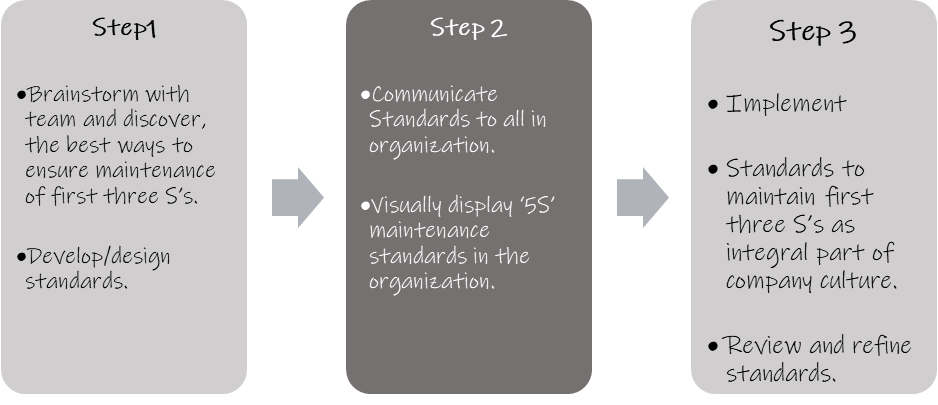

Steps to standardize

Figure 1 – Steps to implement standardization

The key to effectively ‘standardize’ your workplace is to include visual standards everywhere. This includes labels, aisles, and signages. Consequently, they make it easy to sustain 5S. A good implementation of the second S (i.e., set in order) plays a crucial role in achieving standardization.

Tips to ‘standardize’ your workplace:

- Do not tolerate deviation from standards.

- Leaders should lead by example. They should clean their workplace as soon as they reach their desk. On a similar note, every manager and worker in the factory should do this as well.

- If you walk past a deviation, you just set a wrong example! Act on the deviation immediately. Set it right and move on.

Standardize practices everywhere! These pictures show the inclusion of labels, signages, and aisles in a canteen. They help locate the position of chairs and tables adequately:

Standard operating procedures to sustain 5S

It is not possible to standardize an area within a workplace without following the first 3Ss every hour of every day. It is possible only when everyone in the company participates in the 5S journey together.

Once you gain a strong grip over this step, make sure you carry out the final step to the 5S approach –to ‘sustain’.