The first step of the 5S approach is to ‘sort’. The motto of this step is:

“When in doubt, move it out!”

To understand how you should sort your workplace, let’s take a look at a daily example. We’ve all come across an object at home that we don’t need anymore. It is either obsolete or not in a working condition! What do you do? You put it somewhere for now and decide to figure out what to do with it, later! If the object is in good working condition, you may decide to keep it somewhere else till you find its use. This is a common problem. It leads to a pile-up of unnecessary objects over time. Consequently, we run short of storage space. This causes us to create extra storage space without ‘sorting’ the unwanted objects from the previous pile. The reason for this is that we simply don’t have time.

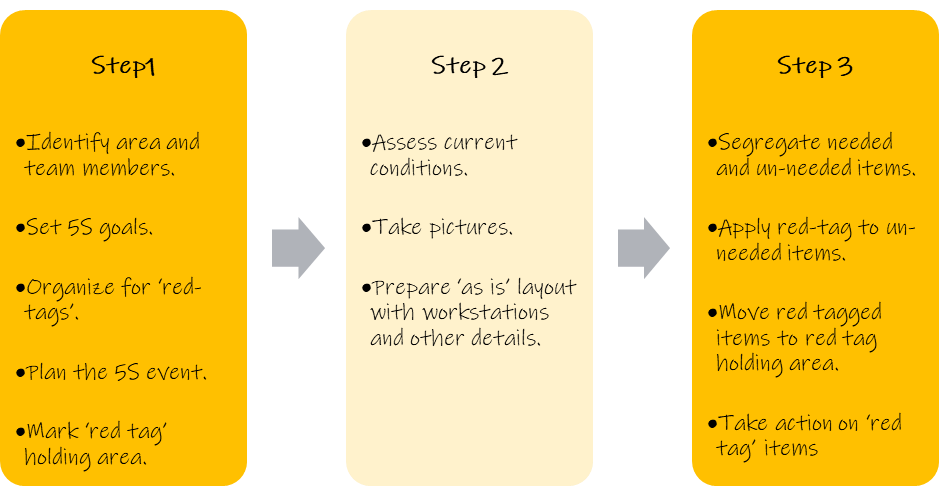

The thumb rule to sort is to act now. Therefore, as soon as you come across any unidentified or unneeded object in your workplace, work to manage it immediately. Find below the 3 steps through which you can sort your workplace.

Steps to sort

Figure 1 – Steps to carry out sorting

How do we decide the location of the items?

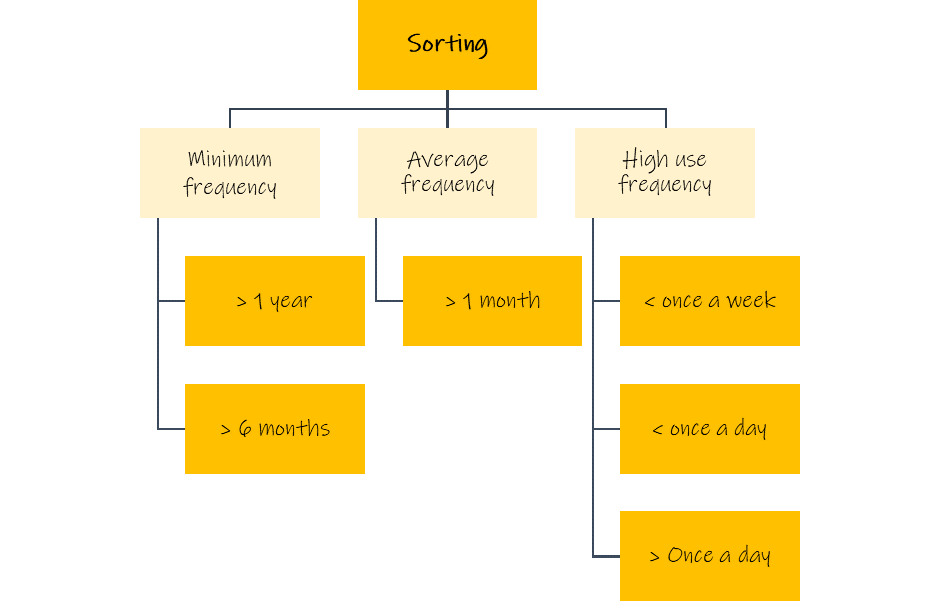

The chart below explains how you should locate and sort items based on their frequency of use:

Figure 2 – Locating and sorting items based on their frequency of use.

- Items closest to the point of use – Frequency of use is once a week, once a day, or more than once a day.

- The items farther to the point of use – Frequency of use is more than once a month.

- Items farthest to the point of use – Frequency of usage is once a year or more than six months. These are not hard and fast rules! You can customize the rules to suit your company.

To sort items, the more frequently used ones should be kept close to the point of use. On the other hand, less frequently used items are to be kept away from the point of use. Lastly, the least or never-used items need to be discarded.

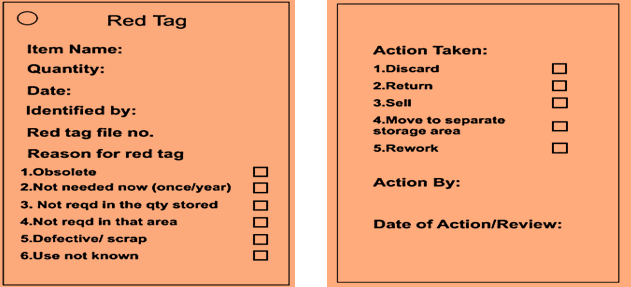

The Red Tagging Procedure

As you sort, apply red tags to the unneeded items that are found near the point of use. It is called a red tag because of its colour – which draws attention. Move the red tag items to a ‘red tag holding area’. This makes it easy to manage them till you decide for them. Use your judgment to use red tags. For instance, in food processing companies, it may be against the regulatory norms.

- Ensure that every decision on red-tag items is taken with iron discipline! More than 90% of 5S implementations fail because the management takes little to no action on the red-tag items. Develop a time-bound action plan and track progress without fail.

- Action on red-tag items with a sense of urgency will significantly help keep the initiative and interests of the people involved in it!

A red-tagged item

A red-tag area

What was the problem of 5S area?

What was implemented, changed or improved under 5S?):

5S Area:

1. Sort

2. Set in Order

3. Shine

4. Standardize

5. Sustain

Benefits Description (e.g. Efficiency at work, Saving of Time etc.)

send easy answer i can understand and send diagram also.