Before you start reading this article, be sure to check out the 1st, 2nd, and 3rd Lean principles! They’ll help you understand the progression of Lean implementation in your workplace in detail.

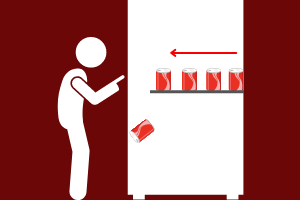

So, let’s come to the fourth Lean principle – pull. Remember the last time you saw any vending machine? What happens when you buy a can of coke? The one in the front row falls, while the ones at the back come forward!

This is a great example of pull. Let’s look at it this way. Who pulls? You; and who are you? The customer! Therefore, it is the customer who pulls. The customer pulls what is needed, how much of it is needed, and when it is needed.

So, what happens when the customer doesn’t pull? The product doesn’t move, and it stays in the storage till expiry. If the product expires, scrap it! This is the biggest waste, as it includes the entire supply chain cost – right from raw materials to the market. Hence the question remains:

Why did the manufacturer produce more than the customer demand?

The fourth Lean principle of pull means producing only to customer demand. Your product or service should be available for purchase as and when needed. Therefore, it should be available in the exact quantities and time as required – neither too early nor too late. If every step aligns with customer demand, then the manufacturer will produce only when there is ‘customer demand’. This is great! A near-perfect solution.

Therefore, pull production is the goal of this Lean principle. Understanding its functionality can help in the smooth implementation of company-wide Lean. Hence, this would help in successfully shaping the company’s future and have vast implications on its key result areas!

Now that you have understood the basics of pull, let us delve into the 5th and final Lean principle – ‘perfection’.