How ERPNext Transformed Inventory Management for SAC.

Industry: IT Services

Author: Ramanujan KK

Publish Date: 14 February, 2025

Introduction

This success story is about a leading manufacturer of incense sticks (Agarbathi) manufacturing company, based in Bengaluru, India. The company, known for its high-quality aromatic products, had been growing rapidly, with its production spread across multiple units and warehouses. However, managing inventory efficiently across these locations was becoming increasingly complex.

After implementing ERPNext with customized solutions tailored to their needs, Agarbathi Innovations experienced significant improvements. Their inventory accuracy had improved, stock discrepancies had been reduced, and warehouse operations had also been streamlined.

In this case study, we explore how ERPNext helped Agarbathi Innovations transform its inventory tracking and location management, resulting in measurable improvements.

About the Company

The client company SAC has been a trusted name in the incense stick industry for over 35 years. They have been supplying both domestic and international markets with premium quality Agarbathi and other incense products. With a reputation for consistency and high standards, SAC operates several warehouses across India. As the demand for their products grew, the company expanded its operations, but with this expansion came a series of inventory-related challenges.

The company was struggling with inaccurate stock levels, inefficient warehouse management, and poor tracking of raw materials and finished products across different locations. Their traditional inventory systems, largely based on spreadsheets, were no longer sufficient to handle the complexity of their operations.

The Challenge of Inventory Tracking and Location Management

Before implementing ERPNext, SAC faced several challenges related to inventory tracking and location management.

- Lack of Real-Time Inventory Visibility: The company had multiple production units and warehouses, but they could not get real-time visibility into stock levels across locations, leading to frequent stockouts and overstocking.

- Inaccurate Stock Reconciliation: Manual tracking of raw materials and finished goods often led to inventory discrepancies, making stock reconciliation and audits time-consuming and error-prone.

- Inefficient Warehouse Operations: With no system in place for tracking product movement between different locations, warehouse managers struggled to ensure optimal stock levels and manage the flow of goods efficiently.

- Raw Material Tracking: Agarbathi Innovations had difficulty tracking raw materials like bamboo sticks, charcoal powder, and essential oils, leading to delays in production due to stockouts or overstocking.

- Delayed Order Fulfilment: With poor inventory visibility and mismanagement of stock at different locations, order fulfillment was delayed, which impacted customer satisfaction.

Why SAC Chose ERPNext

SAC decided to implement ERPNext due to its robust inventory management features, customizability, and flexibility.

They were looking for a solution that could:

- Provide real-time stock tracking across multiple locations.

- Offer customization for raw material and finished goods inventory management.

- Streamline warehouse operations by automating stock movements and transfers.

- Integrate production processes with inventory, ensuring timely raw material availability.

After evaluating multiple ERP systems, SAC chose ERPNext because of its user-friendly interface, comprehensive features, and strong community support. Additionally, ERPNext’s ability to offer customized inventory management suited their specific needs.

How ERPNext Responded

Once SAC implemented ERPNext, we, the team of SKIL Global, worked closely with them to customize the system to meet their specific inventory management needs.

Mentioned below is a detailed description of how we tackled their challenges.

- Multi-Location Inventory Tracking: We customized the Inventory module in ERPNext to enable real-time tracking of stock across multiple warehouses and production units. Each location had its inventory dashboard, making it easier for managers to track stock levels, monitor usage, and plan accordingly.

- Raw Material and Finished Goods Tracking: We customized ERPNext to create inventory categories for raw materials (e.g., bamboo sticks, charcoal powder, essential oils) and finished goods (incense sticks, cones, and other products). The system automatically tracked raw material consumption based on production schedules. This ensured that materials were always available when needed.

- Automated Stock Replenishment: Using ERPNext’s automated alert system, we set up reorder levels for raw materials and finished goods. When inventory reached the minimum threshold, the system automatically triggered purchase orders. This reduced stockouts, maintaining continuous production.

- Inventory Reconciliation: We implemented automated inventory reconciliation processes. This allowed SAC to compare physical stock with the recorded stock in the system. Any discrepancies were flagged for investigation, reducing manual audits and improving inventory accuracy.

- Production and Inventory Integration: ERPNext’s production module was linked directly to inventory. This integration allowed the company to track how much raw material was used in production. In turn, giving them a clear view of the material flow and ensuring that production schedules were aligned with available inventory.

The Results

The improvements were immediate and measurable. Here’s how ERPNext’s customized solution positively impacted SAC’s inventory management:

- 25% Reduction in Stockouts: By implementing real-time inventory tracking and automated stock replenishment, the company reduced stockouts by 25%, ensuring that production lines were never halted due to material shortages.

- 30% Improvement in Inventory Accuracy: Barcode scanning and automated reconciliation processes led to a 30% improvement in inventory accuracy, reducing discrepancies between actual stock and system records.

- 20% Reduction in Overstocking: With automated stock alerts and better visibility, SAC reduced overstocking by 20%, optimizing warehouse space and reducing carrying costs.

- 15% Faster Order Fulfillment: Improved inventory visibility and streamlined warehouse operations resulted in 15% faster order fulfillment times, allowing the company to meet customer demands more efficiently.

- 40% Reduction in Manual Effort for Stock Audits: With real-time inventory updates and automated reconciliation, stock audits became 40% faster, saving both time and labor costs.

- 50% Improvement in Raw Material Utilization: Automated tracking of raw materials reduced waste and improved the overall utilization rate by 50%, leading to cost savings in material procurement.

- 10% Reduction in Warehousing Costs: Optimized stock levels and better warehouse management led to a 10% reduction in overall warehousing costs, improving the company’s bottom line.

Conclusion

After associating with the ERPNext team at SKIL Global, Agarbathi Innovations got results that were significant and measurable. The company was able to tailor the solution to its unique requirements. This in turn led to a system that perfectly aligns with its business processes and drives significant improvements in efficiency and profitability. They reduced stockouts and improved inventory accuracy. They also saw faster order fulfillment and lower operational costs.

This success story here clearly demonstrates the power of ERPNext. It helps in streamlining inventory management for businesses of all sizes, particularly those with complex supply chains and multiple locations. ERPNext also serves as a valuable example for other businesses seeking to improve their inventory management processes and gain a competitive edge in the market.

If you are interested to achieve similar success stories, write to us!

Optimizing R&D and Production: A Lean Approach to Polymer Manufacturing

Industry: Polymer

Author: Aryan Jain

Publish Date: 21 November, 2024

Introduction

This B2B polymer manufacturing company, with over four decades of experience, provides synthetic polymers such as epoxy resin, silicone, and polyurethane to clients across India, Europe, and the USA. With an annual revenue of ₹36 crore, the company sought to address challenges related to operational efficiency, manufacturing costs, and scalability.

The goal was to transition from a people-dependent model to a system-dependent one, allowing sustainable growth and enhanced operational throughput. The CEO, recognizing the need for external expertise, sought assistance from SKIL Global, a consulting firm with a strong track record of implementing lean methodologies and operational improvements in manufacturing companies.

The journey that unfolded highlights the company’s transformation. They embraced lean principles, focusing initially on optimizing manufacturing and research and development (R&D), which were identified as the key drivers of the company’s growth potential.

The Background: A Vision for Transformation

The polymer company was recently acquired by a new managing director. As a highly driven individual, he focused on improving operational output. He also wanted to achieve growth in competitive global markets. His vision was to turn the company into a leader in customized synthetic polymers. This could be achieved only by offering high-quality, innovative products at competitive prices.

This growth-oriented mindset led the new managing director to prioritize operational efficiency as a critical lever for achieving global competitiveness.

The Managing Director’s Goal

Given the dynamic nature of the synthetic polymer industry, the managing director understood two important things. What he realized was that, both continuous innovation in R&D and process optimization, were two non-negotiable factors for long-term success.

He had an ambitious goal. This goal was to transform the company from a traditional, people-driven organization to a system-driven enterprise. This enterprise would be one that could consistently deliver results, regardless of personnel changes or market fluctuations.

The Role of SKIL Global: Assessing the Current State

SKIL Global, upon being brought in by the CEO, began with a comprehensive assessment of the company’s operations. This involved engaging with leaders from every department—manufacturing, R&D, procurement, sales, and logistics. This was done to get a full understanding of how each function contributed to the company’s output and where inefficiencies existed.

Findings after the assessment

- The process began with detailed process mapping, which revealed several bottlenecks and redundant processes, particularly in manufacturing and R&D.

- A lack of reliable data collection systems was also noted. This which made it difficult for the leadership team to make informed decisions about production levels, employee performance, and resource allocation.

- Without access to accurate data, performance tracking and identification of improvement opportunities were extremely limited.

As part of the current state assessment, SKIL Global worked with department heads and the managing director to create a list of key performance indicators (KPIs). These KPIs would serve as benchmarks for success and enable the team to track progress over time.

The KPIs were primarily focused on improving manufacturing throughput, R&D efficiency, raw material utilization, and equipment effectiveness.

Key Challenges Identified

The initial assessment revealed several challenges across the organization:

- Lack of Data for Performance Tracking: One of the first significant challenges was the absence of any real-time data tracking for operations. Without data, it was impossible to measure the effectiveness of current processes or track improvements over time. This lack of insight made it difficult for the leadership team to prioritize changes or investments.

- Underutilization of R&D: The R&D department was central to the company’s innovation pipeline but was operating inefficiently. The team was only able to process 2-3 R&D batches per day. This was due to poor planning, a lack of coordination between departments, and delays caused by inadequate preparation of raw materials.

- Manufacturing Bottlenecks: In the manufacturing department, there were delays in batch production due to machine downtime, inconsistent raw material availability, and a lack of standardized procedures. Equipment utilization was low, with machines operating at only 50% capacity, further limiting production potential.

- People-Dependent Operations: The company heavily relied on the expertise and availability of specific personnel to maintain daily operations. This dependency made it difficult to scale operations and posed a significant risk if key employees were absent or left the company.

Implementing Lean Methodologies: A Strategic Approach

To address these challenges, SKIL Global began implementing lean methodologies. This included a set of principles focused on minimizing waste, optimizing processes, and enhancing overall efficiency.

These lean principles were applied across multiple departments, but the initial focus was on R&D and manufacturing, where the greatest potential for immediate improvements lay.

1. Data-Driven Decision Making

One of the first steps was setting up a data collection system that would provide real-time insights into various aspects of operations. This involved automating data collection where possible and creating simple, manual data entry processes where automation was not feasible.

With this new system in place, the company was able to start tracking KPIs for batch production, raw material utilization, equipment downtime, and employee performance.

The introduction of these metrics provided the company with a clear baseline, which allowed the team to track incremental improvements and assess the impact of the changes being made.

2. R&D Optimization

The R&D department, a critical part of the company’s growth strategy, was identified as a key area for improvement. The department was initially processing only 2-3 R&D batches daily due to inefficiencies in raw material handling, equipment readiness, and project coordination.

SKIL Global implemented several changes to address these issues:

- Raw Material Kitting: One of the most effective changes was the introduction of raw material kitting. This involved pre-preparing the raw materials needed for the next day’s R&D batches. By having everything ready in advance, the team was able to reduce the time spent on weighing and measuring materials, leading to faster batch processing.

- Better Coordination with Manufacturing: The R&D team began coordinating more closely with manufacturing to align their project timelines with equipment availability and raw material procurement. This helped avoid delays caused by equipment being unavailable or materials not being on hand.

As a result of these improvements, the number of R&D batches processed daily increased from 2-3 to 4-5, and equipment utilization improved from 50% to 75-80%.

3. Manufacturing Improvements

The manufacturing department observed the following improvements:

- Introduction of the lean tools helped to streamline batch production and reduce machine downtime.

- Equipment maintenance schedules were optimized to ensure machines were operating at peak efficiency.

- Standard operating procedures (SOPs) were established for batch production to ensure consistency and reduce errors.

These changes not only improved production output but also led to better quality control and reduced waste.

Manufacturing throughput increased, and the company was able to meet customer demand more effectively without needing to increase staffing levels.

Financial Impact

The financial impact of these improvements was significant. Within one year of implementing the lean methodologies, the company’s annual revenue grew from ₹36 crore to ₹42 crore—a 16.7% increase. This growth was attributed to the increased throughput in both manufacturing and R&D, as well as the reduction in operational inefficiencies.

Ongoing Engagement

The engagement with SKIL Global has now been ongoing for 1.5 years, with multiple contract extensions reflecting the company’s satisfaction with the results.

As the initial phase of improvements in manufacturing and R&D has proven successful, the managing director has shifted the focus to optimizing other areas of the business, including supply chain management, customer service, and product innovation.

Conclusion

The transformation of this polymer manufacturing company highlights the power of strategic alignment, data-driven decision-making, and lean methodologies in driving operational improvements.

The company focused on core areas like R&D and manufacturing. It shifted from people-dependent operations to system-dependent processes. This in turn led to a significant improvement in efficiency. The company also experienced an increase in revenue. As a result of which the company is now well-positioned for long-term growth in competitive global markets.

This story serves as a testament to the impact of continuous improvement and the importance of fostering a culture of innovation and collaboration across departments.

If you are interested to achieve similar success stories, write to us!

Reduce Batch Failures in Biosimilar Manufacturing

Industry: Biosimilars & Pharmaceutical Manufacturing

Buyer Persona: Quality Assurance Managers, Manufacturing Process Engineers, and Operations Directors

Author: Madhava Krishna

Publish Date: 17 October, 2024

Reducing Biosimilar Batch Failures to Improve Throughput by 5.73%

Introduction

The Pharmaceutical Biosimilar Company faced significant challenges in controlling batch failures, which led to reduced throughput and financial losses.

After implementing Lean Six Sigma methodologies, the company experienced a 5.73% reduction in batch failure rates and a financial benefit of ₹7.58 crores annually.

This case study outlines the collaboration, tools, and results achieved by optimizing their biosimilar production process.

The Story of Pharmaceutical Biosimilar Company

The Pharmaceutical Biosimilar Company is a leading player in the biosimilar market, manufacturing drugs that replicate biologic medical products. Prior to engaging with Skilglobal, the company was experiencing a high batch failure rate of 8.1%, resulting in wasted resources and lower manufacturing efficiency.

As a result, the company was struggling to meet production targets and faced increased costs. To combat these challenges, the company decided to collaborate with Skilglobal to implement Lean Six Sigma solutions aimed at reducing batch failures, enhancing detection, and preventing failures before they occurred.

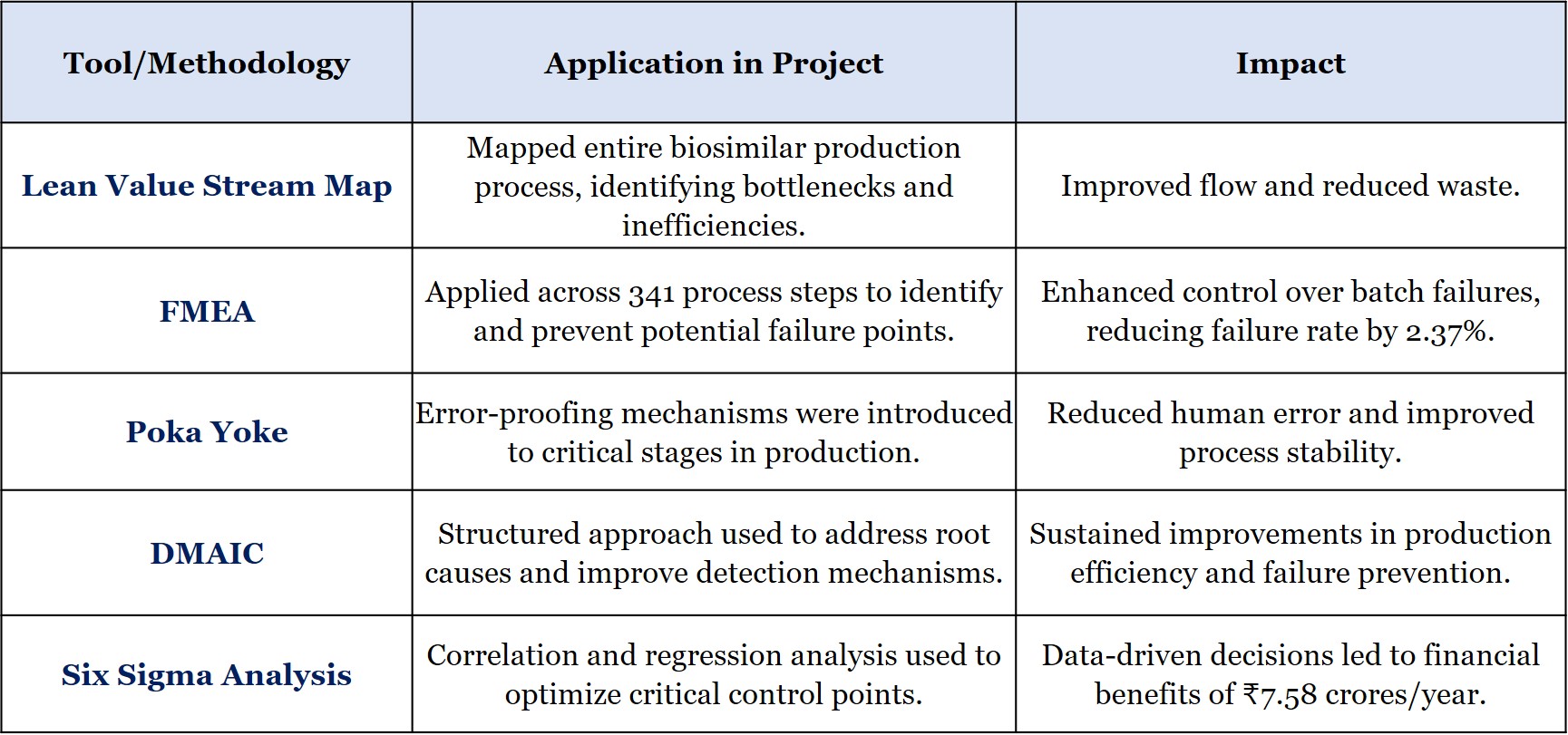

Success Metric #1: Batch Failure Reduction

Before implementing SKIL Global’s Lean Six Sigma methodology, the failure rate of biosimilar batches was 8.1% (7 out of 74 batches). Skilglobal introduced a DMAIC (Define, Measure, Analyze, Improve, Control) approach to tackle the underlying issues.

Key steps included:

- Conducting a detailed Lean Value Stream Map analysis to identify bottlenecks.

- Implementing Failure Mode Effect Analysis (FMEA) to determine failure points across 341 process steps.

By enhancing controls and focusing on error-proofing (Poka Yoke), batch failures were reduced to 5.73% (7 out of 122 batches). This improvement boosted throughput significantly.

The Client Speaks:

“SKIL Global’s structured approach helped us reduce our batch failures and improve overall productivity. Their team helped us identify the key issues and apply actionable insights to improve our process efficiency.”

Success Metric #2: Financial Impact

The reduction in batch failures had a direct and positive impact on the company’s bottom line. With failures reduced by 2.37%, the company achieved annual financial savings of ₹7.58 crores. This result was made possible through targeted improvements in the detection and control of failure modes using Lean and Six Sigma tools.

Additionally, process improvements were made to reduce inventory costs and optimize overall manufacturing operations.

Success Metric #3: Training and Capability Building

To sustain the improvements, the team at the Pharmaceutical Biosimilar Company was trained on Lean Six Sigma techniques, with several members earning Green Belt certifications.

SKIL Global also provided specialized training on why-why analysis for root cause determination, which empowered shop floor operators to proactively prevent future failures.

Learning & Development Impact:

- Lean Six Sigma Green Belt certifications for key team members.

- Enhanced team capabilities in failure mode detection and resolution.

Figure 1: Tool Application Table

Overall Results

By implementing Lean Six Sigma methodologies, the Pharmaceutical Biosimilar Company successfully reduced batch failures, optimized throughput, and achieved significant financial gains. These efforts not only led to immediate operational improvements but also established a framework for continuous improvement in their biosimilar production lines.

The company continues to benefit from its improved processes, better-trained staff, and cost savings, all of which position it for future growth.

If you’re facing similar challenges in your manufacturing process, write to us! Learn how you can achieve the same significant improvements in productivity and cost savings by implementing Lean Six Sigma tools.

Optimizing Logistics Costs to Boost EBITDA: A Case Study on Rural E-commerce and Warehouse Distribution

Industry: Rural E-commerce and Warehouse Distribution

Buyer Persona: CEO, OPEX, Managers, Transport HOD, CFO

Author: Madhava krishna D A

Publish Date: July 2024

Introduction

A Rural B2B E-commerce and Warehouse Distribution company operating in South India serves as a one-stop solution for all rural consumer needs, providing extensive consumer choice, multiple SKUs, and enhanced categories, all delivered to the doorstep of Kirana stores.

As the first entrant in the market, the company established 100 distribution centers across South India. Rapid expansion from 50 to 100 distribution centers aimed to meet growing demand and drive topline growth while continuously enhancing its distribution network. The company had investments to drive the expansion and now the CEO wants to make it profitable in the next 3-5 months in order to start yielding return to the stakeholders.

Need: Make the Business model profitable

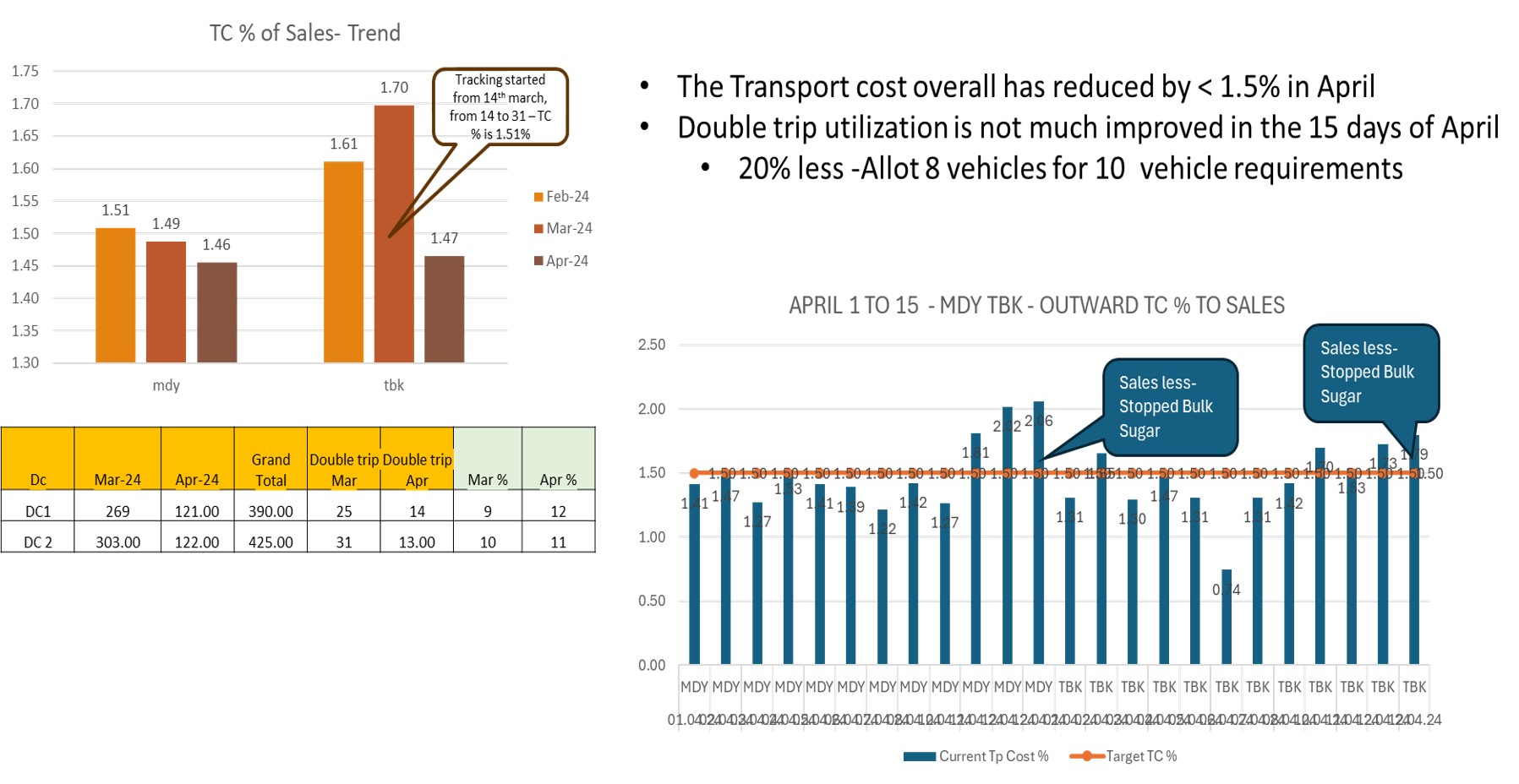

Prior to working with Vilcart Solutions, rural businesses often faced challenges with inefficient and costly logistics, leading to stock shortages and delayed deliveries. The high cost of outbound logistics, which was at 2.5%, significantly affected their profitability and operational effectiveness.

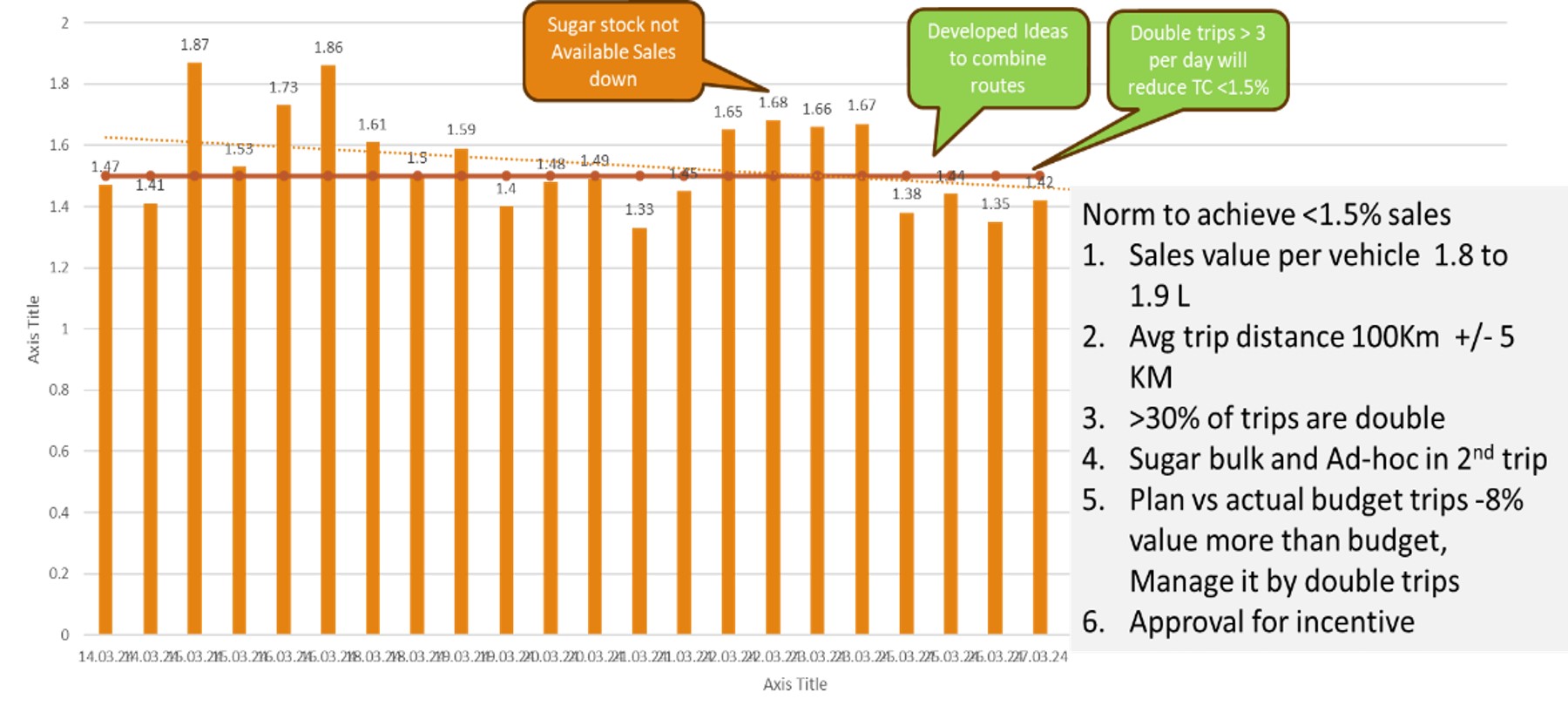

To address these issues and tap into the potential for growth, businesses sought to optimize their logistical operations. By partnering with SGBS, they wanted to implement standardized logistics routes that would reduce transportation costs from 2.5% to 1.5%.

They also wished to develop a new cost management logistic model for consistent cost efficiency across all distribution centers, improving overall profitability and operational efficiency.

Why the Rural E- commerce company Chose SKIL Global (SGBS)

Customers often discovered Skilglobal (SGBS) through industry referrals, online research, and word-of-mouth recommendations from other businesses facing similar challenges in logistics.

As these businesses sought innovative solutions to optimize their supply chains and reduce costs, they came across Skilglobal’s reputation for effectively managing rural distribution through a sophisticated e-commerce and logistics platform. SGBS has even worked with other leading E-commerce companies in India

They indulged in a current state assessment to identify the gaps in the present business processes. During the activity SGBS recognized their logistics inefficiencies and high transportation costs as major obstacles to growth and profitability.

Approach to the challenge

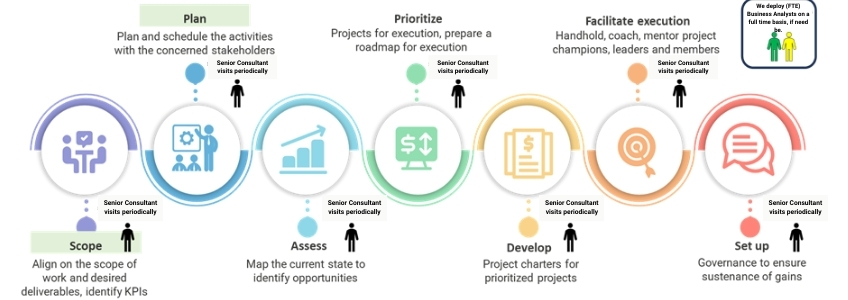

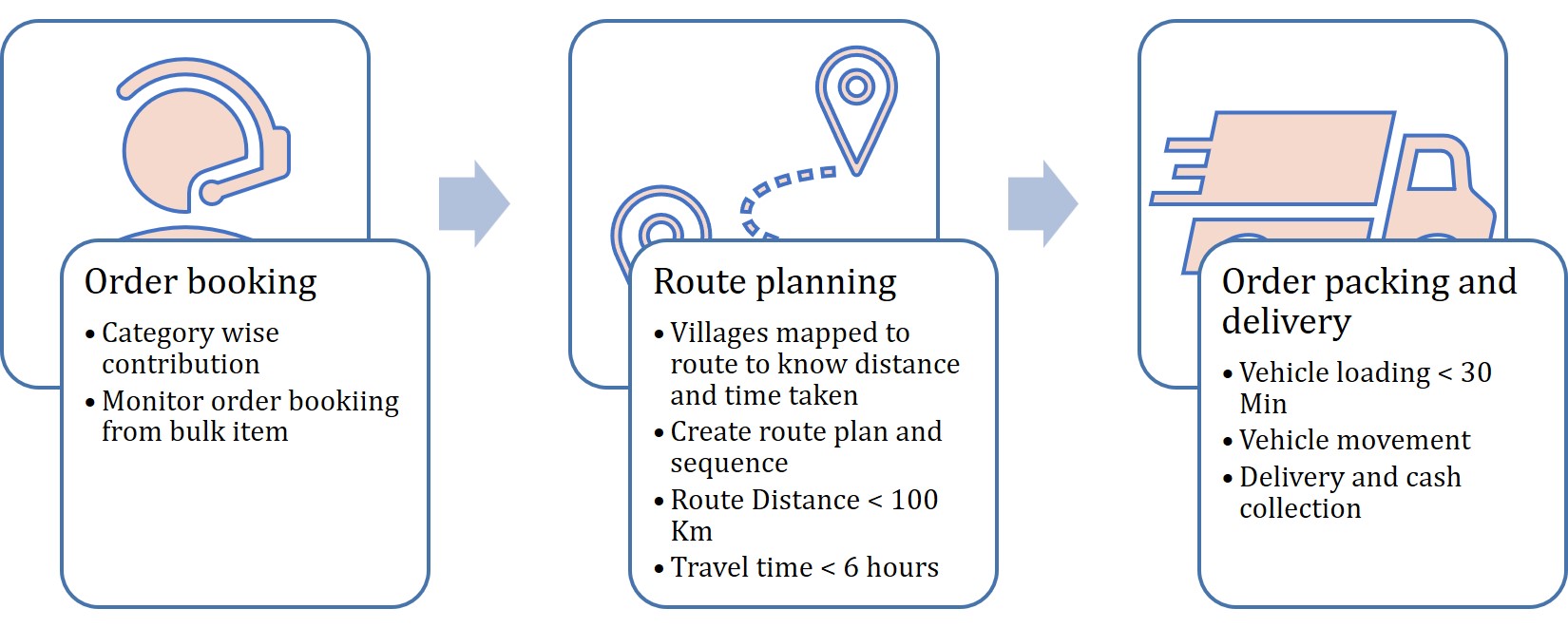

Figure-1: Approach to problem solving

Assessment and prioritization

SGBS approach to consulting involves the above phases. Here, we are in the phase of ‘Assess’ and ‘Prioritize’. SGBS conducted a current state assessment for the client to evaluate their existing processes and identify opportunities for improvement using lean methodology.

The summary of the assessment is outlined below. Transport cost optimization was prioritized to bring maximum impact on the profitability of the business.

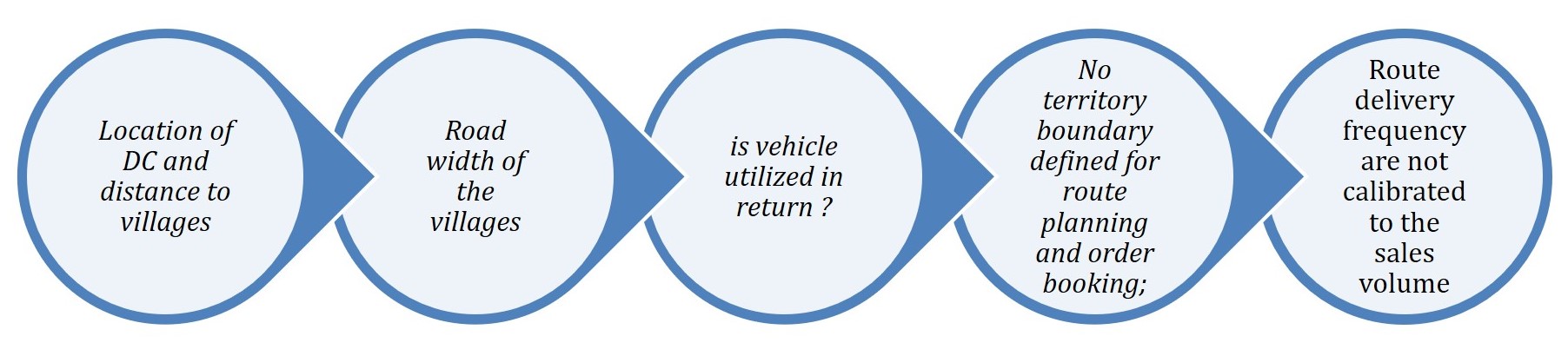

Figure-2: Current state assessment summary tree

Develop the Model of profitability

The process began with identifying the factors influencing transportation costs associated with outbound deliveries from the warehouse of the e-commerce company. A significant challenge was the remote location of the Distribution Center (DC), chosen to provide employment opportunities in rural areas.

Below is the fishbone cause and effect analysis conducted during a Kaizen event with the team.

Figure-3: Cause and effect diagram

Data collection

A data collection plan was implemented to capture information on the current performance of critical factors, identified through the cause-and-effect analysis. The following data was collected and analyzed:

- Map current routes in the Distribution Center (DC) by road distance.

- Map vehicle type to village based on road size.

- Baseline current route performance using metrics of quality, cost and delivery.

- Develop a tracking method for key transport metrics:

- Transport cost as a percentage of sales:

- By route

- By DC

- Transport sales value per trip and per kilometer.

- Transport cost as a percentage of sales:

Summary of Baseline Findings

- Transport cost exceeds 3% of sales across routes and DC.

- Route and trip planning were non-standardized.

- Vehicle allocation was based on daily sales tonnage and bill value.

- Transport sales value per trip and per kilometer was 30% lower than expected.

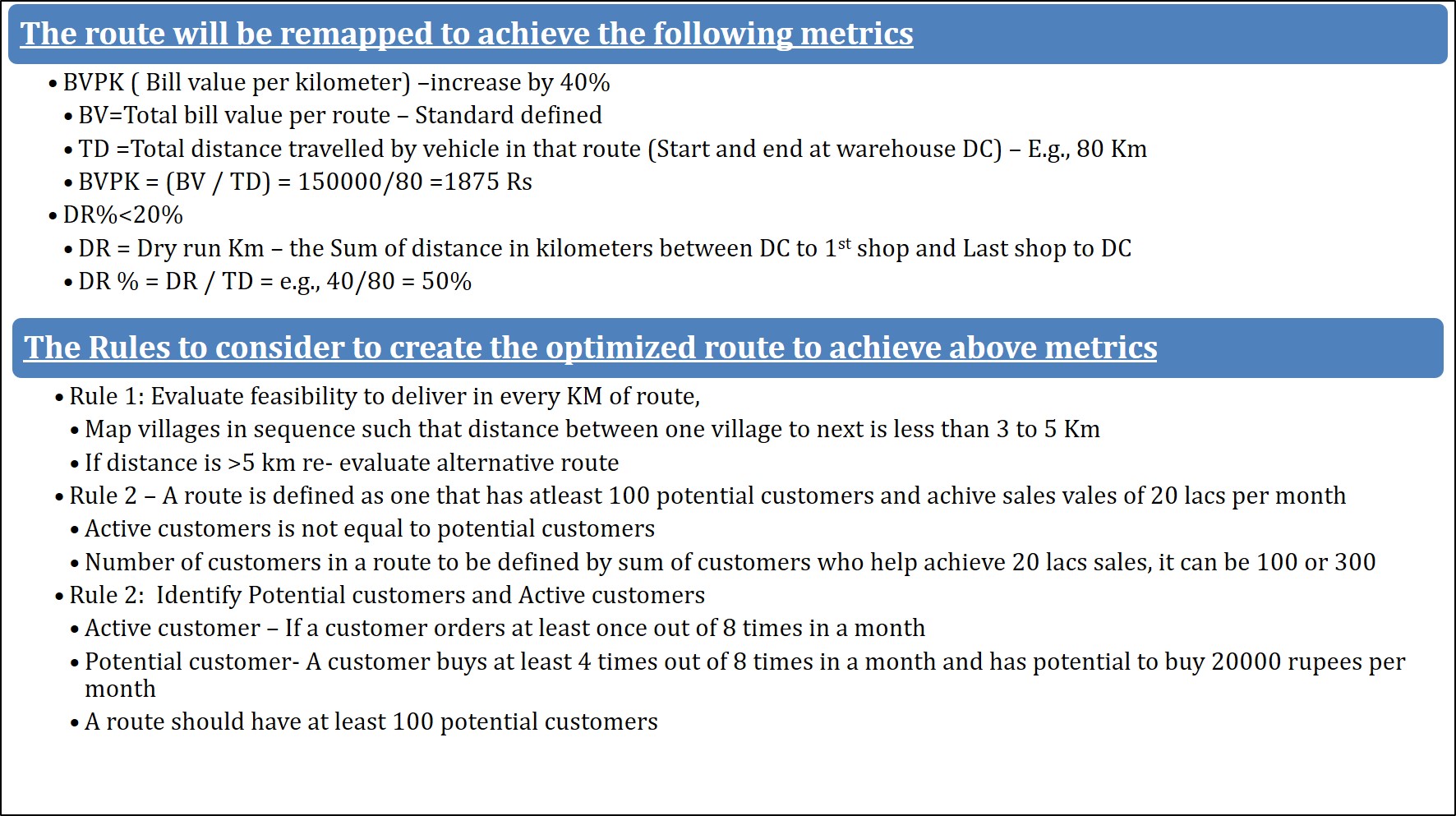

Brainstorming the ideas for the New efficient model

Reasons for Higher Logistic costs:

Summary of the Brainstorming Session for Proposed Logistics Model

Objective:

To develop a comprehensive and efficient logistics model that addresses current challenges and optimizes operations.

A kaizen event with the team was conducted. The brainstorming session provided valuable insights and actionable steps towards developing a more efficient logistics model.

The proposed solutions aim to reduce costs, improve route planning, and enhance overall logistics performance

Participants:

- Logistics Team

- Operations Managers

- Supply Chain Analysts

- IT Support

- External Consultants

Key Discussion Points

-

Current Challenges:

-

- High transportation costs

- Inefficient route planning

- Non-standardized vehicle allocation

- Low transport sales value per trip and per kilometer

-

Proposed Solutions:

-

- Route Optimization:

- Implement advanced route planning methods.

- Standardize routes based on historical data and real-time traffic conditions.

- Cost Reduction Strategies:

- Negotiate better rates with transport providers.

- Optimize load capacity to reduce the number of trips.

- Technology Integration:

- Use GPS tracking for real-time monitoring.

- Implement a centralized logistics management system.

- Performance Metrics:

- Develop KPIs for transport cost, delivery time, and vehicle utilization.

- Regularly review and adjust strategies based on performance data.

- Route Optimization:

-

Action Plan:

-

- Short-term:

- Conduct a pilot test of the proposed route optimization software.

- Begin negotiations with transport providers.

- Long-term:

- Fully integrate the logistics management system.

- Continuously monitor and refine the logistics model.

- Short-term:

The Results

The ideas were piloted and cross deployed, here is the summary of the results:

Write to us and discover how our innovative logistics model transformed our operations, reducing transport costs from 2.5% to 1.5% of sales. This significant reduction has not only enhanced our profitability but also positively impacted our EBITDA.