Optimizing Logistics Costs to Boost EBITDA: A Case Study on Rural E-commerce and Warehouse Distribution

Industry: Rural E-commerce and Warehouse Distribution

Buyer Persona: CEO, OPEX, Managers, Transport HOD, CFO

Author: Madhava krishna D A

Publish Date: July 2024

Introduction

A Rural B2B E-commerce and Warehouse Distribution company operating in South India serves as a one-stop solution for all rural consumer needs, providing extensive consumer choice, multiple SKUs, and enhanced categories, all delivered to the doorstep of Kirana stores.

As the first entrant in the market, the company established 100 distribution centers across South India. Rapid expansion from 50 to 100 distribution centers aimed to meet growing demand and drive topline growth while continuously enhancing its distribution network. The company had investments to drive the expansion and now the CEO wants to make it profitable in the next 3-5 months in order to start yielding return to the stakeholders.

Need: Make the Business model profitable

Prior to working with Vilcart Solutions, rural businesses often faced challenges with inefficient and costly logistics, leading to stock shortages and delayed deliveries. The high cost of outbound logistics, which was at 2.5%, significantly affected their profitability and operational effectiveness.

To address these issues and tap into the potential for growth, businesses sought to optimize their logistical operations. By partnering with SGBS, they wanted to implement standardized logistics routes that would reduce transportation costs from 2.5% to 1.5%.

They also wished to develop a new cost management logistic model for consistent cost efficiency across all distribution centers, improving overall profitability and operational efficiency.

Why the Rural E- commerce company Chose SKIL Global (SGBS)

Customers often discovered Skilglobal (SGBS) through industry referrals, online research, and word-of-mouth recommendations from other businesses facing similar challenges in logistics.

As these businesses sought innovative solutions to optimize their supply chains and reduce costs, they came across Skilglobal’s reputation for effectively managing rural distribution through a sophisticated e-commerce and logistics platform. SGBS has even worked with other leading E-commerce companies in India

They indulged in a current state assessment to identify the gaps in the present business processes. During the activity SGBS recognized their logistics inefficiencies and high transportation costs as major obstacles to growth and profitability.

Approach to the challenge

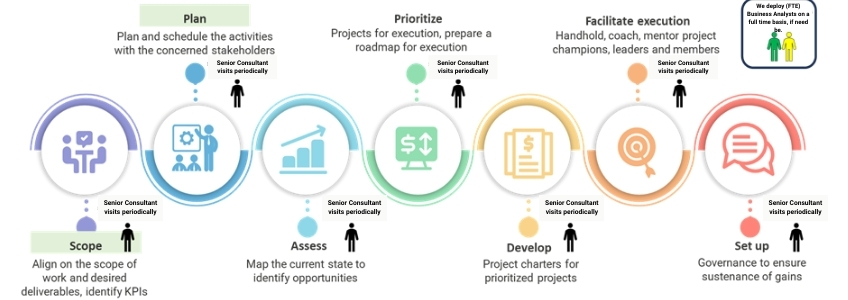

Figure-1: Approach to problem solving

Assessment and prioritization

SGBS approach to consulting involves the above phases. Here, we are in the phase of ‘Assess’ and ‘Prioritize’. SGBS conducted a current state assessment for the client to evaluate their existing processes and identify opportunities for improvement using lean methodology.

The summary of the assessment is outlined below. Transport cost optimization was prioritized to bring maximum impact on the profitability of the business.

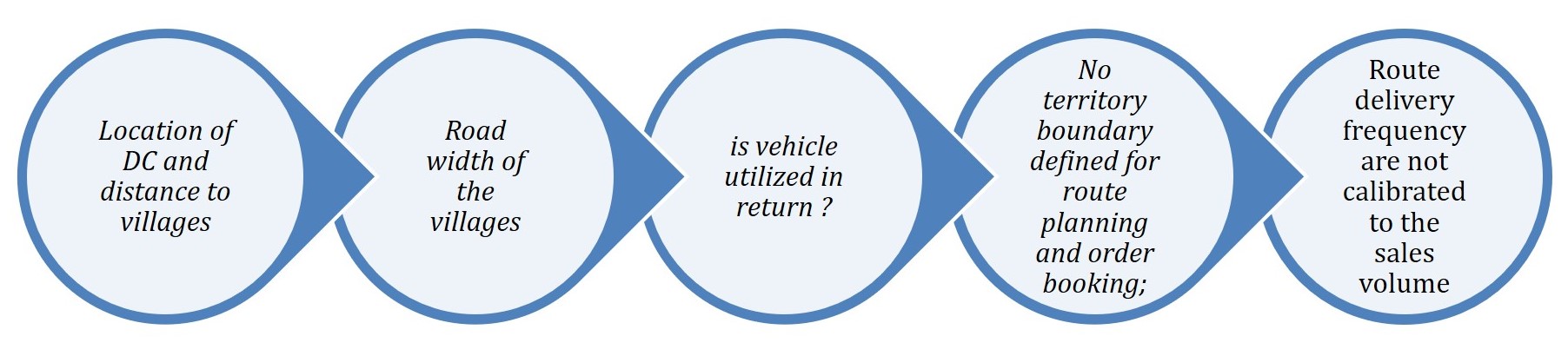

Figure-2: Current state assessment summary tree

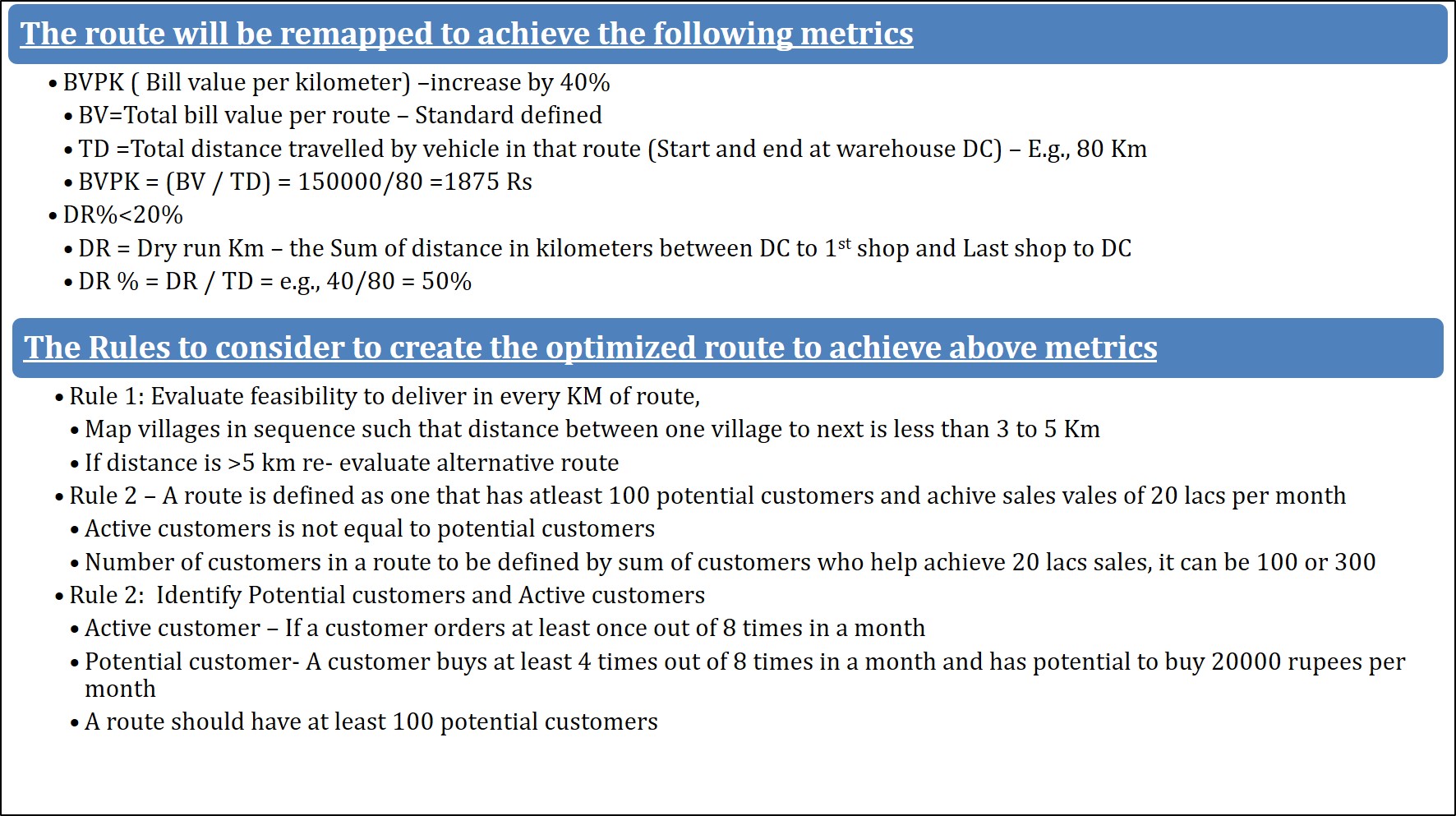

Develop the Model of profitability

The process began with identifying the factors influencing transportation costs associated with outbound deliveries from the warehouse of the e-commerce company. A significant challenge was the remote location of the Distribution Center (DC), chosen to provide employment opportunities in rural areas.

Below is the fishbone cause and effect analysis conducted during a Kaizen event with the team.

Figure-3: Cause and effect diagram

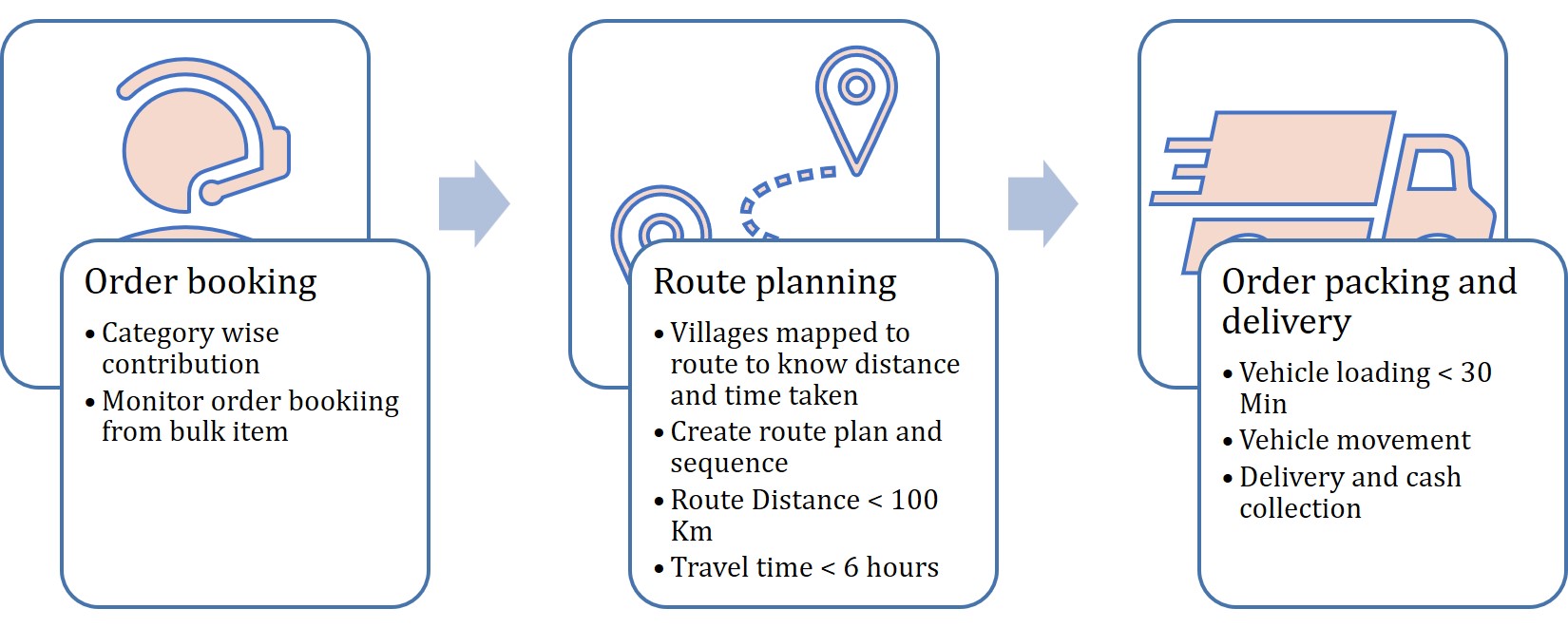

Data collection

A data collection plan was implemented to capture information on the current performance of critical factors, identified through the cause-and-effect analysis. The following data was collected and analyzed:

- Map current routes in the Distribution Center (DC) by road distance.

- Map vehicle type to village based on road size.

- Baseline current route performance using metrics of quality, cost and delivery.

- Develop a tracking method for key transport metrics:

- Transport cost as a percentage of sales:

- By route

- By DC

- Transport sales value per trip and per kilometer.

- Transport cost as a percentage of sales:

Summary of Baseline Findings

- Transport cost exceeds 3% of sales across routes and DC.

- Route and trip planning were non-standardized.

- Vehicle allocation was based on daily sales tonnage and bill value.

- Transport sales value per trip and per kilometer was 30% lower than expected.

Brainstorming the ideas for the New efficient model

Reasons for Higher Logistic costs:

Summary of the Brainstorming Session for Proposed Logistics Model

Objective:

To develop a comprehensive and efficient logistics model that addresses current challenges and optimizes operations.

A kaizen event with the team was conducted. The brainstorming session provided valuable insights and actionable steps towards developing a more efficient logistics model.

The proposed solutions aim to reduce costs, improve route planning, and enhance overall logistics performance

Participants:

- Logistics Team

- Operations Managers

- Supply Chain Analysts

- IT Support

- External Consultants

Key Discussion Points

-

Current Challenges:

-

- High transportation costs

- Inefficient route planning

- Non-standardized vehicle allocation

- Low transport sales value per trip and per kilometer

-

Proposed Solutions:

-

- Route Optimization:

- Implement advanced route planning methods.

- Standardize routes based on historical data and real-time traffic conditions.

- Cost Reduction Strategies:

- Negotiate better rates with transport providers.

- Optimize load capacity to reduce the number of trips.

- Technology Integration:

- Use GPS tracking for real-time monitoring.

- Implement a centralized logistics management system.

- Performance Metrics:

- Develop KPIs for transport cost, delivery time, and vehicle utilization.

- Regularly review and adjust strategies based on performance data.

- Route Optimization:

-

Action Plan:

-

- Short-term:

- Conduct a pilot test of the proposed route optimization software.

- Begin negotiations with transport providers.

- Long-term:

- Fully integrate the logistics management system.

- Continuously monitor and refine the logistics model.

- Short-term:

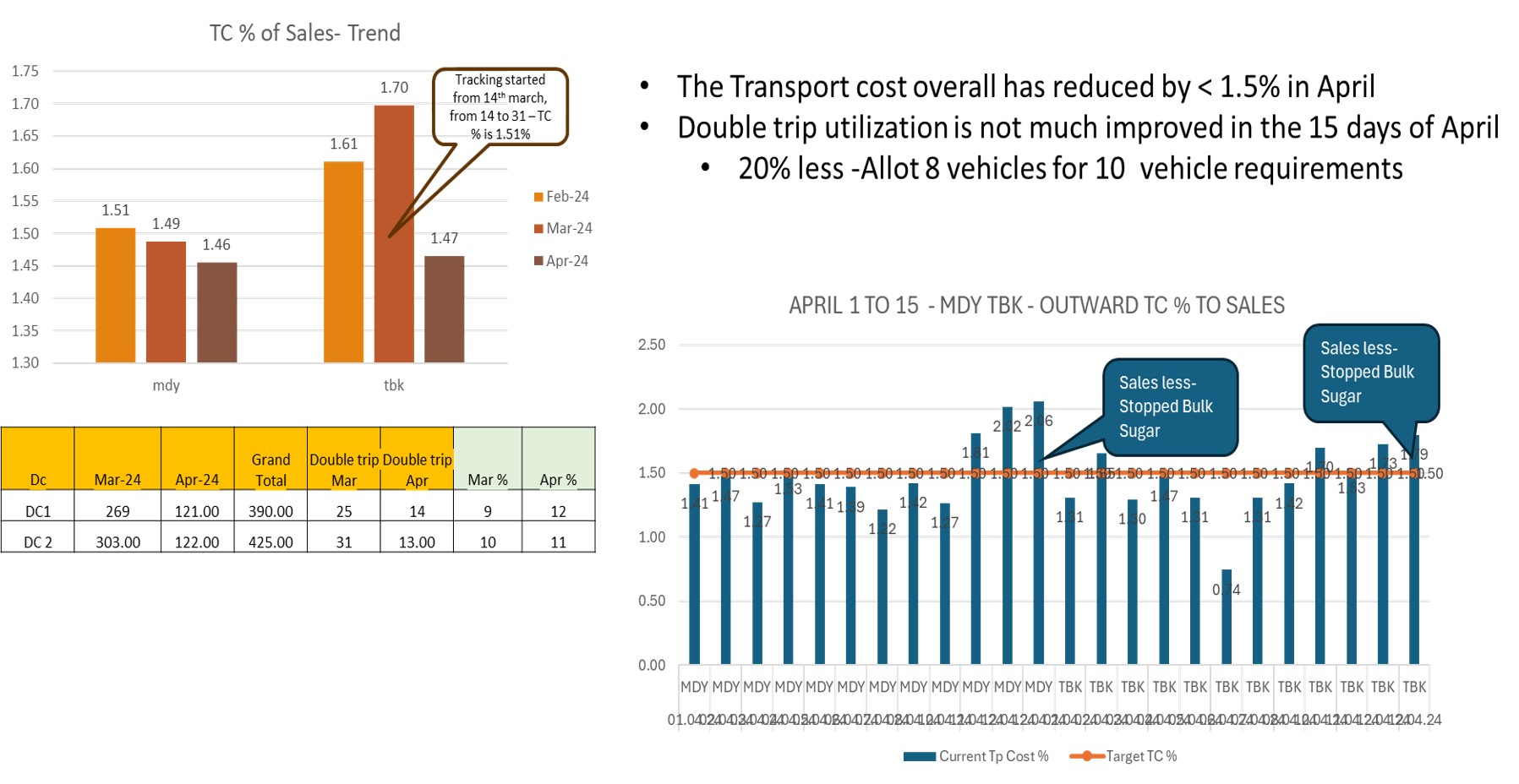

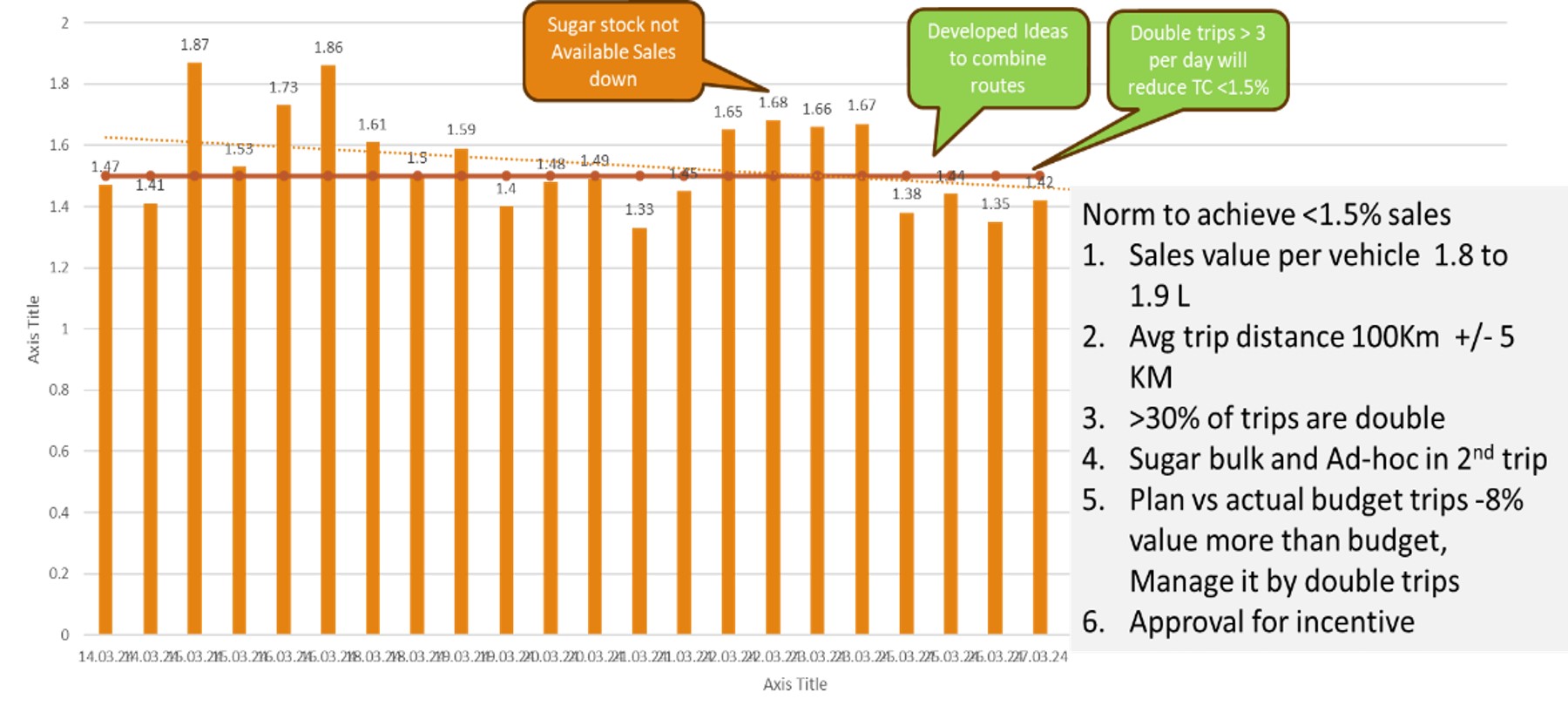

The Results

The ideas were piloted and cross deployed, here is the summary of the results:

Write to us and discover how our innovative logistics model transformed our operations, reducing transport costs from 2.5% to 1.5% of sales. This significant reduction has not only enhanced our profitability but also positively impacted our EBITDA.