Standard work is one of the most important types of Lean tools. Every work must have certain standards, based on which they are executed. What to produce? How much? What are the steps? How much is the demand? What is the time for each step? These are the areas that standard work deals with.

Standard Work Documents:

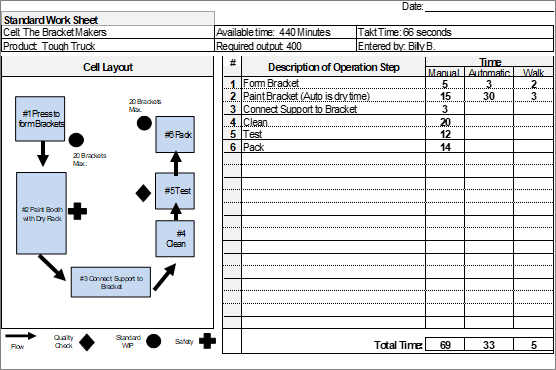

A standard work document captures the needed standards to carry out a job successfully. Find below an example of a standard work document:

Figure 11 – Example of a standard work document

In this example:

- 400 units need to be produced per day. The takt time is 66 seconds. Therefore, you need to produce 1 unit every 46 seconds to meet the customer demand.

- The available time is 440 minutes.

- There are 6 steps in the process.

- The workplace layout is shown with the help of symbols.

- Various symbols represent the following: safety, standard WIP, quality check, and flow.

- You can see the time split between manual, automatic, and walking steps.

- The cell layout shows how the various steps are organized within the workplace.

A standard work document makes it easy for even a layperson to do a job with minimal training. You should develop and display a standard work document near the point of use. This is an important visual aid that explains how a job should be carried out! Furthermore, standard work is the foundation for continuous improvement. A continuous improvement journey takes place from an existing ‘standard work’ to a ‘new standard work’. Consequently, it is modified with improvements.

Standard Work in Services

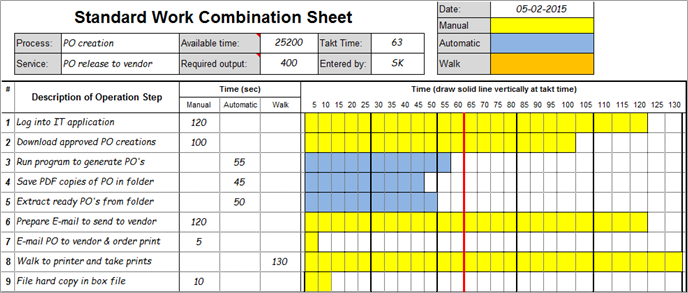

Standard work applies to services as well. Consider the following example:

Figure 2 – Example for a standard work for services

In this example:

- You can find the available time, takt time, needed output, and other details.

- The columns to right represent time in seconds.

- On the left-hand side, you’ll find the various steps needed to raise a purchase order. Firstly, ‘log into IT application’. It is a manual step and takes 120 seconds, as can be seen in the horizontal bar extending to 120 seconds in the graph.

- The vertical, red bar shows the takt time to be 63 seconds.

- The cycle time at steps 1, 2, 5, and 8 is greater than the takt time! Do Kaizens improve and create a ‘new standard’?

The 6 Steps of Standard Work

Ideally, standard work is never static. To carry out ‘standard work’, the following steps are useful:

- Firstly, identify the operation or process step that needs standard work documentation. Assign duties to the different team members and leader.

- Secondly, schedule a video shoot of the operation as it takes place – right from the start to the end.

- Thirdly, review the video for time and motion studies with the team.

- Fourthly, document the standard work.

- Fifthly, review it and obtain the necessary approvals.

- Lastly, publish it!