To implement Lean, what are your top 3 goals this year?

Ever wondered how to implement Lean effectively in an organization? This is the most decisive question that will determine an organization’s performance. Therefore, it shares a definitive interrelationship with one’s project execution abilities. A good way to start is to know the ‘Voice of Customer’ and ‘Voice of Business’. Once you differentiate them, translate them to the current year’s strategic goals and objectives.

I asked this question about Lean to the Managing Director of a reputable company, and this was the answer I received: “Production, Quality, and Cost!” [Let us call this the ‘Voice of Business’]

Following this, I further asked him:

“What are your desired production numbers?”

To that, he responded:

“A minimum average production of 4000 units from XYZ, and 6000 units from ABC per day.” [Let’s call this the current year’s goals and objectives.]

“[and to] keep a goal of 97% right-first-time quality”, he added! In this case, I suggest one uses a CSVSM (Current State Value Stream Mapping) to identify improvement opportunities aligned with the company’s goals and objectives.

If you find yourself in this scenario, here is what you need to do to implement Lean effectively:

First off, make sure you look into the 3 key areas that address the successful ways to implement Lean. Following this, prioritize the areas where Lean implementation is necessary. While doing so, keep the following things in mind:

- Align the projects with the current year’s goals and objectives – this will make it easier to apply Lean tools.

- Do not take up all projects where you want to apply Lean at once! Instead, list projects for every three months.

- Assign people to these projects, and define the review structure. These could be daily, weekly, and/ or monthly reviews. Daily reviews on the listed projects would be at the shop floor level, weekly at the factory level, and monthly reviews with senior leadership.

Following this, roll out the Kaizens, projects, and initiatives where Lean needs to be applied. This is where project execution plays a crucial role.

Project Execution

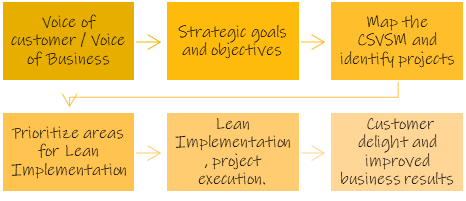

With Lean implementation being emphasized upon with such vigour, you might find yourself wondering how Lean can be used on project execution. Here’s a flow chart that outlines the 6 steps you need to follow to effectively achieve Lean implementation on project execution:

Keep in mind that you should visit some key questions regarding Lean implementation once every quarter – “is the customer satisfied? Have the desired business results been achieved?”.

If the answers are ‘Yes’, you are moving in the right direction with your Lean implementation.

However, if the answers are ‘No’, then find out what is missing with your Lean implementation. Revisit whether you chose the right projects. Is it that the execution is failing? There could be several reasons. Make suitable strategic or tactical adjustments based on the investigation.

When and Where Should I Use Lean?

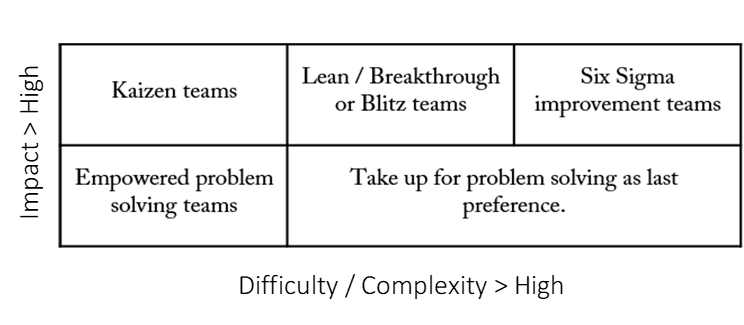

It is important to remember that Lean implementation may not solve every problem you have! For a deeper understanding, refer to the matrix below.

- If both the difficulty/ complexity and impact are low, use empowered problem-solving teams.

- When the difficulty/ complexity is high and the impact is low, make sure to avoid them. Therefore, execute them as the last priority.

- If both the difficulty/ complexity and impact are high, use qualified six sigma professionals OR Lean professionals who lead big and complex projects.

- When the difficulty/complexity is low and the impact is high use Kaizen teams. This is a great place to start!

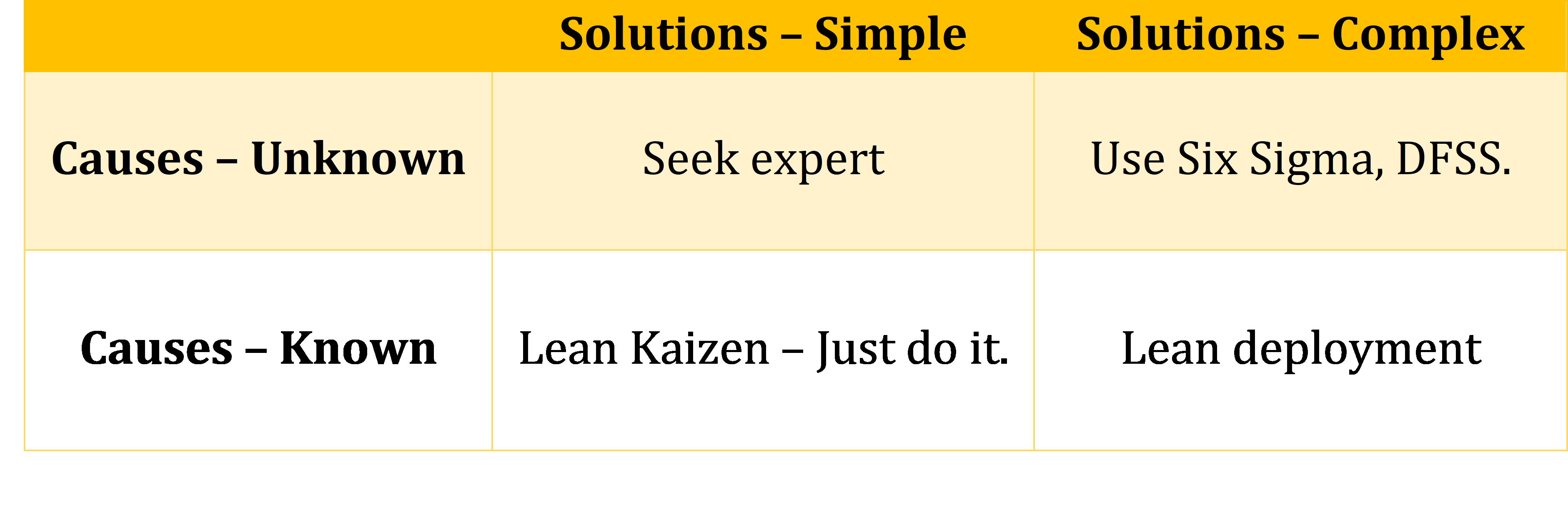

- If a solution is simple and causes are unknown, be sure to seek expert recommendations.

- When a solution is complex and causes are unknown, use methodologies such as ‘Six Sigma’.

- If a solution is simple and causes are known, you can employ ‘Lean Kaizens’ or ‘Just do it’.

- When a solution is complex and causes are known, use companywide Lean implementation. Here is another perspective! Refer to the matrix below:

Now that you have understood the 6 steps to successful Lean implementation, what comes next? Find out the 2 key result areas which depend upon your ability to implement Lean effectively!