Certified Lean Expert

Training and Certification Program in Lean Management

Whether it be a new managerial job you are looking for or moving up the position in your organization, the prospect candidate is expected to be knowledgeable and hands on in Continuous Improvement methods like Lean Manufacturing or Management. Management expects employees to not only manage their roles but to also improve process.

Is this certification right for me?

Lean training and certification are highly recommended for those in Operations Excellence/ Operations/ Production/ Quality/ Inspection/ Management role. Knowledge in Lean can help you improve Quality, Efficiency and Delivery.

For Operators & Supervisors, Lean knowledge can help you achieve your daily targets and responsibilities effectively

If you are employed in a Middle or Senior management role involved in strategy making and implementing

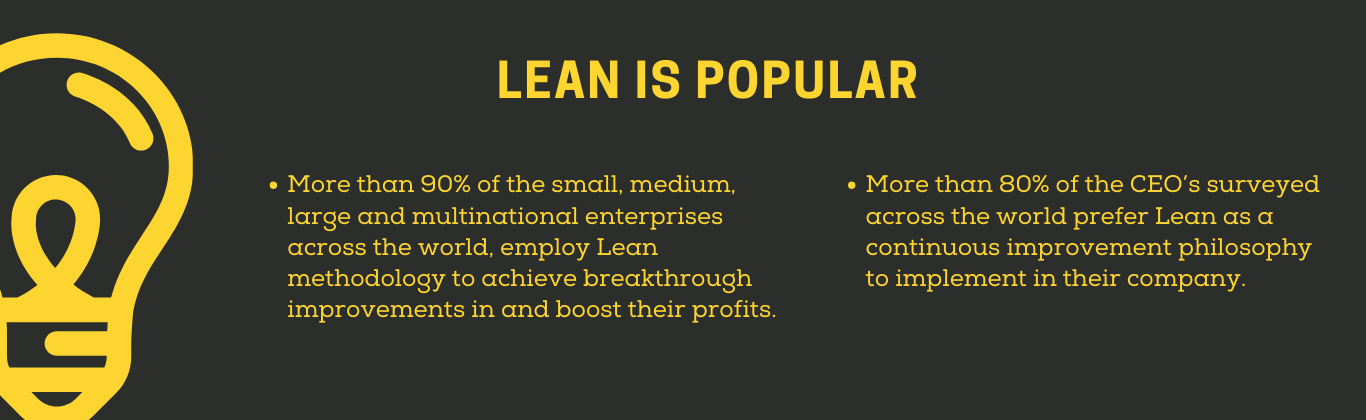

More than 90% of the small, medium, large and multinational enterprises across the world, employ Lean methodology to achieve breakthrough improvements in and boost their profits. If you are looking for change, Lean Certification is the way to go.

Why Training and Certification in Lean

Exceed expectations

Applying Lean tools will help you achieve breakthrough improvements in efficiency, quality and turnaround time in your own work area. You will exceed expectations with the use of Lean tools.

Job Security

Working professionals having skills in Lean have higher job security than others. Because as a Lean practitioner, you are always in a hunt to add value to your company

Get on A Team

Knowledge is one of the key criteria to consider for A team. With Lean knowledge, you have an edge over others!

Confidence and Self – Esteem

Once you achieve most of what is mentioned above, you will gain confidence. Lean credentials, success stories, higher confidence, getting into A team will boost your chances of getting hired in a global organization.

Why SKIL

Experience - Consulting hours

Professionals coached

Segments worked with

Career path options

Training & Certification in Lean enhances your existing job role. If you are keen to explore roles specific to Lean Management skills, you could consider:

- Lean implementation Consultant.

- Lean Leader

- A career in process excellence.

- A career in operations excellence.

- Quality Assurance Manager.

- Continuous Improvement Manager.

- Operations excellence manager.

- Business excellence manager.

- Six Sigma Black Belt.

- Six Sigma Master Black Belt.

- Business Head / CXO, as you persevere in the journey and churn improvement stories where ever you go.

Duration and Pre-requisites

Course Duration

- Classroom based-5 days weekends.

- Instructor-Led Live web sessions 40 hours (each session is 4 hours).

Calendar

- Classroom based – Across a month

- Instructor-Led Live web sessions – Across two and half months

Work experience

- Work experience is necessary. A minimum of 1 year of experience is preferred.

- Understanding of business cycle is required.

Education

- Preferred Minimum education – Graduate from any university

- Diploma/ Graduate

- Post Graduate/ Masters

Lean Training Levels

Every role in the organization has responsibilities and requirements. We believe a common course curriculum or body of knowledge cannot address needs of the role. Hence, we have broken down the body of knowledge into three levels. Depending on years of experience and role, one can choose a level of training to undergo

Certified Lean Expert – Level 1

- Recommended for New joiners, Trainees, Apprentices, Agents, Floor executives, Associates, Operators, Supervisors

- Duration – 1 day

Certified Lean Expert – Level 2

- Recommended for Line, Operations, Shift, Assistant managers other lower and middle level managers

- Duration – 3 day

Certified Lean Expert – Level 3

- Recommended for Middle and Senior management, Operations Excellence team members, Black belts, Quality executives,

- Duration – 5 days (Classroom) or 40 hours (Web based)

Body of Knowledge

| 1. Lean and its history | 3. Current State Value Stream mapping | 5. Future State Design |

|

|

|

| 2. Lean Principles | 4. Lean Tools | 6. Lean Deployment |

|

|

|

| 1. Lean and its history | 3. Current State Value Stream mapping |

|

|

| 2. Lean Principles | 4. Lean Tools |

|

|

| 1. Lean and its history |

|

| 2. Lean Principles |

|

Key features of the program

Placement Assistance

Certification exam included

Expert course design

Free “Lean Made Simple” book

Learn by doing – Exercises & Games

4 hours of coaching and mentoring