Before you start reading this article on flow, be sure to check out the first and second Lean principles! It’ll help you gain a more holistic understanding of Lean implementation.

The identification of the barriers and facilitators of flow is extremely important. The first step is to map the current state value stream. This is essential. After doing so, look for where the flow of work stops and why. From experience, work either ‘flows’ or it ‘waits’ – i.e., waiting for the next step, decision, material, information, rework, etc. Even if the work flows, transformation may not take place. This could be in the cases of moving material from one place to another or ‘sending e-mails’.

Remember: Lack of flow means lack of transformation!

Lack of flow is caused by the following reasons:

- Excess Transport – move material from one place to another.

- Excess Inventory – store in quantities more than necessary.

- Excess Motion – the unergonomic workplace.

- Waiting – for decision, information, machine breakdown, changeover.

- Over-processing – unnecessary operation.

- Overproduction – producing more than the next step can handle.

- Defects – not right the first time.

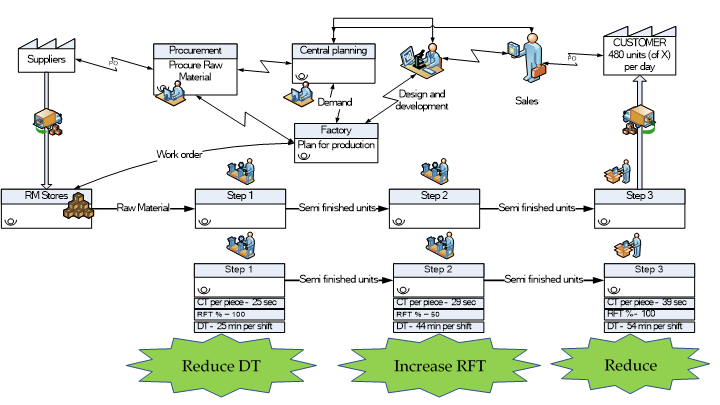

When identifying the barriers to this third Lean principle, look for these ‘wastes’ in your current state value stream. Apply starbursts to highlight what is causing ‘waiting’ or lack of flow. There will be many! Don’t worry about what you will do with them. Just identify and show them in your value stream map as ‘opportunities’ that act as barriers to flow. Refer to the figure below:

After this, we graduate to the 4th Lean principle – pull. Following this, make sure to check out the 5th and final Lean principle as well, to ensure that your organization can use Lean to successfully shape its future!