Total productive maintenance is an effective Lean tool that is primarily in charge of dealing with machine breakdown. Therefore, it is very closely related to overall equipment effectiveness.

Overall Equipment Effectiveness (OEE)

To understand overall equipment effectiveness, refer to the figure below. It shows the various losses that may be faced by a machine:

Figure 1: Overall Equipment Effectiveness

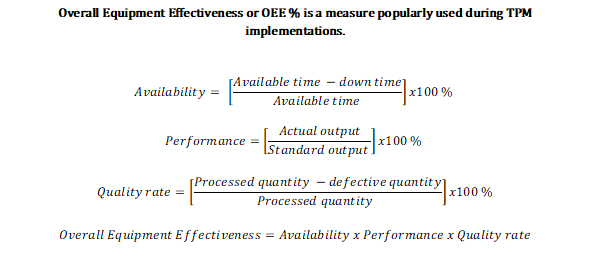

Overall equipment effectiveness primarily deals with tackling these various losses. There are 3 types of losses associated with machines. These are losses of availability, quality, and performance.

Firstly, regarding availability losses, the goal of TPM is to have no breakdowns. Secondly, in the case of performance losses, the goal is to prevent minor stops and running machines at less than entitled speeds. Lastly, on account of quality losses, the target of TPM is to reinforce zero defects. Overall Equipment Effectiveness % ties up these three measures

The table below explains the relationship between total productive maintenance, its goals, and types of productivity losses:

Table: Overall Equipment Effectiveness elements

When Should You Use Overall Equipment Effectiveness?

You can use Overall Equipment Effectiveness if these are the kind of questions you find yourself asking these questions:

- Do you track unscheduled machine downtime by every piece of equipment you use?

- Do you track your changeover time?

- How reliable are they?

- Do you use this information to rank and carry out an improvement?

If your answer to these questions about OEE is a ‘no’ or ‘not sure’, carrying out Overall Equipment Effectiveness needs to be a part of your plan of action! Treat this as your first step. Afterwards, once you have the information, compile it in a tabular format. You can refer to the OEE % calculations shown below. Don’t forget to use your judgment to define these features, based on which ones are suitable to your business and products. Most importantly, considerations may vary depending on your business process.

Here’s an example of an OEE calculation:

- Potential production time = 480 minutes.

- Tea time = 30 minutes

- Break time = 30 minutes

- Quality stop = 47 minutes

- Hourly standard = 60 parts per minute

- Total output = 19271 parts

- Scrap parts = 432 parts