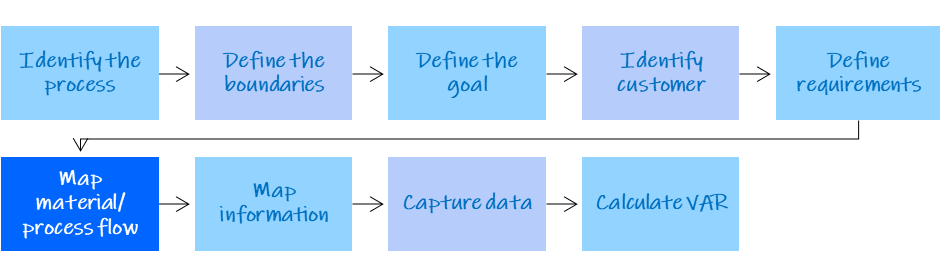

Step 6 to making a current state value stream map is to map the material/ process flow. However, make sure you check out the first, second, third, fourth, and fifth steps to gain a more holistic understanding of your CSVSM. Here’s a recap of the steps that I recommend you to follow initially while making your CSVSM:

Figure 1 – Steps to construct a CSVSM

Step 6: Map the Material, Information, and Process Flow

A material/ process flow transforms a given input to output. In manufacturing, both input and output are physical objects. Services, on the other hand, could be physical files or digital information. Today’s digital world enables information in the service sector to move from one mailbox to another, or from server to server.

What kind of material are we talking about?

By material, we mean:

- Raw material or customer image/ information for services

- Semi-finished work or partially completed work for services

- Consumables or input information for services

How does material move in manufacturing?

From:

- One step to the next step

- One machine to another machine

- Machine to the storage point

- Storage point to the machine

- Suppliers to the storage point, and vice versa

- Storage point to the customer

- Storage point to another storage point

Important note: Before you start to map the process flow on the map, take a quick tour of the process. Review everything from the ‘start to finish’ for what is in scope. Keep sticky notes in hand. Use one note per step, and fill the notes as you walk through the process. Once you’re done, place them sequentially on a chart paper based on how they operate.

Click here to read the 7th step to making your current state value stream map – i.e., mapping the information!