The present case focuses on a newspaper company we worked with to solve their problem of delivering newspapers on time. In the first part of our case study, we covered the observations that we made during the 4-step newspaper-printing process. These included:

- First, to prepare the plates: here, the images of a newspaper would be printed on a metal sheet, and they would make notches.

- Second, to load the plates: the metal sheets would be loaded into the machine.

- Third, to print the newspaper: here, the full newspaper would be printed.

- Last, to pack and dispatch: the newspapers would be packed and sent to their respective delivery locations.

Additionally, we covered the various NVA activities in each of these steps of the newspaper printing process.

Mapping the current state value stream

To map the current value stream, I gathered a stopwatch, notepad, pencil and an eraser. After that, I stood by every step and collected data. Don’t worry if you don’t get it right the first time. Do it once again, until you’re confident about the data!

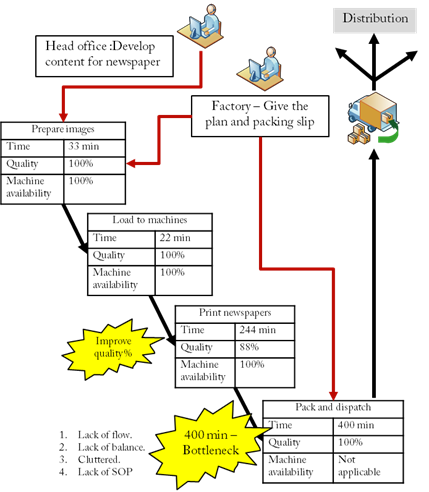

Look at the value stream mapping steps and data below. Which process step is the bottleneck? If you thought it’s the ‘pack and dispatch’ step, you’d be right! It takes 400 minutes for a defined unit of work. Remember, it isn’t just the cycle time that decides the bottleneck. You must also see the other measurable performance limits as well. For instance, a process step may show the least cycle time. However, if it also has the worst quality, it could still be a bottleneck! Therefore, you should look at all the limits in the process data box to identify the bottleneck step. Refer to part 1 of this case study to recap the VA and NVA activities in each of the process steps.

Figure 1: VSM of a newspaper printing process

However, solving each of these NVA steps may not necessarily lead to on-time delivery of newspapers. Hence, the real question remains –what is causing the issue? Refer to the current state value stream map below! So, what was the bottleneck? It was the ‘pack and post’ step as suspected.

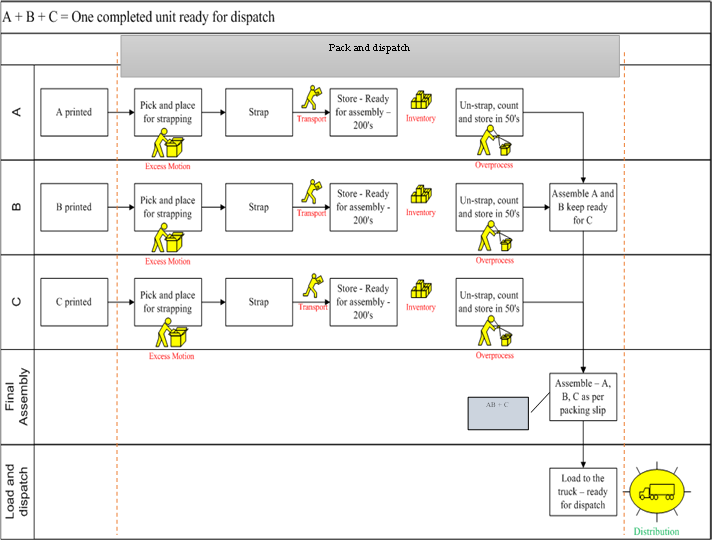

Figure 2: Pack and dispatch process

Here’s an elaborate explanation of the 4th step of the newspaper printing process:

- A + B + C make one complete newspaper. A and B print roughly around noon. Afterwards, they are moved to the storage and wait for C.

- Once A, B and C are ready, according to the packing list, they are loaded onto the truck and dispatched.

- Packing: Let’s say a customer needs 215 copies. The printing machine continuously produces, but it straps them in the quantities of 200 each. Note that a pack of 200 is the standard bundle. Therefore, the final assembly will have a standard bundle of 200 copies, and 15 extra newspapers alongside it.

- The customer needs 215 copies.

- The final assembly = (200 A + 200 B + 200 C) + (15 A + 15 B + 15 C); Standard bundles + Parcel/ loose sets.

- Therefore, load to truck #123, and then deliver them. The A3 template below captures this progress:

- Packing: Let’s say a customer needs 215 copies. The printing machine continuously produces, but it straps them in the quantities of 200 each. Note that a pack of 200 is the standard bundle. Therefore, the final assembly will have a standard bundle of 200 copies, and 15 extra newspapers alongside it.

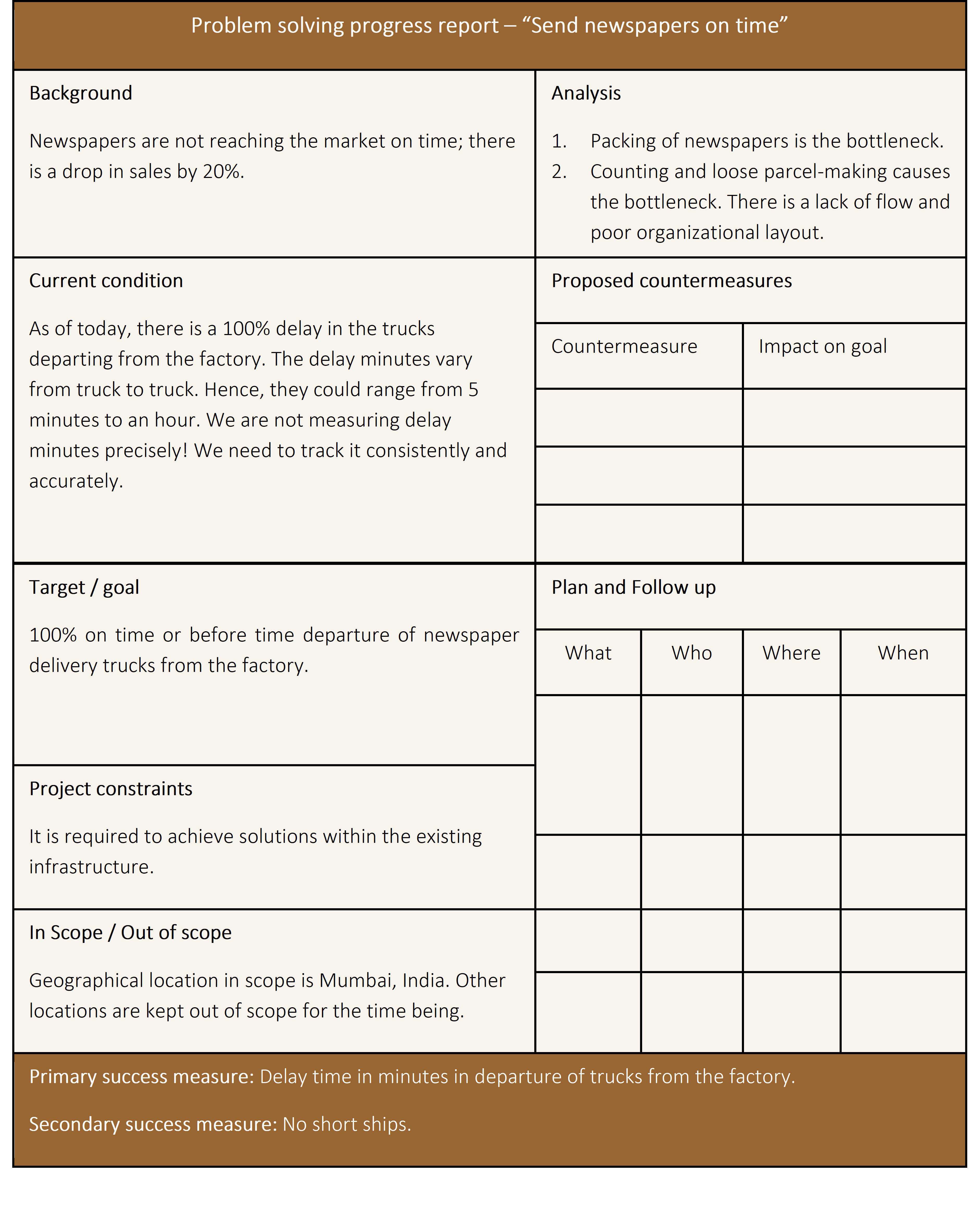

Table: Applying A3 in the newspaper case