Successful Lean deployment is one of the most crucial determinants of organizational success. The following steps will help you deploy Lean in your day-to-day work area, department, or even company as a whole!

STEP 1:

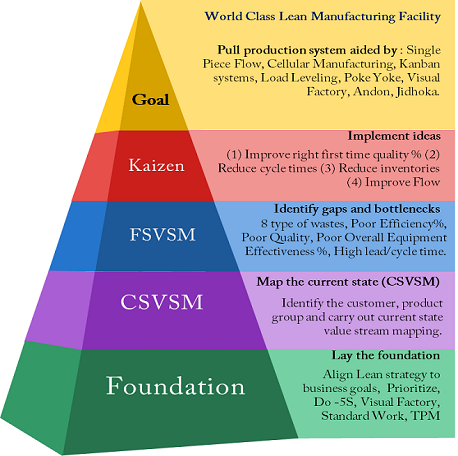

Firstly, lay a foundation. In particular, make sure you align the Lean strategy to your business goals, priorities, and carry out 5S, visual factory practices, standard work, and total productive maintenance.

STEP 2:

Secondly, map the current state. Be sure to identify the customer, product group, and carry out current state value stream mapping!

STEP 3:

Thirdly, define the future state! Here, you need to pinpoint the goal – what is it that you wish to achieve? Consequently, identify what the barriers in the current state are and what the various wastes in the value stream might be that may hinder the process of attaining this goal. Figure out what and where change is needed.

STEP 4:

Lastly, implement ideas! You should use a Kaizen Blitz approach here. Therefore, stay focused right from the start, form teams, assign team leaders, and promote teamwork. Don’t rest till you implement the ideas!

Without successful Lean deployment, a roadmap, and laying a solid foundation, it’s impossible to achieve a world-class manufacturing facility. Therefore, Lean is your program of the month.

Figure 1: Lean implementation roadmap

Common Pitfalls during Lean Implementation

It’s important to ask yourself, “when does Lean fail?”. Here’s a look at the reasons for Lean implementation failures, which have been elaborated upon against the stages of a pyramid.

Figure 2: Why does Lean implementations fail? Here are the common pitfalls.

Critical Success Factors for Lean Implementation

Some of the critical success factors in Lean placement are given below.

- Firstly, align Lean to your short-term and long-term goals and objectives.

- Secondly, carry out necessary practices such as 5S, visual factory, and TPM.

- Thirdly, make sure you execute Lean behaviors to achieve results.

- Fourthly, the top management should take account of the success or failure of the Lean implementation. Therefore, simply assuming the role of sponsors isn’t enough. They must actively engage in the initiatives.

- Fifthly, assign internal champions to lead the initiative. These are the people who are the heads of various departments.

- Next, only training isn’t enough! Everyone needs to take action with a sense of urgency.

- Sixthly, ask yourself if the progress is visible. Are you headed in the right direction? Make sure you carry out regular reviews at least once a week to answer these questions.

- Next, involve everyone! It doesn’t matter who’s who. In this case, the more the merrier!

- Following this, carry out implementation in Kaizen mode. You shouldn’t let Lean adjust to your way of working. Instead, adjust your way of working to the Lean way!

- Lastly, it isn’t possible to succeed in Lean deployment if you have a poor understanding of Lean tools. So, make sure you’ve got adequate expertise in the area before its implementation.