Maintaining inventory accuracy is vital because the company’s financial decisions and operational efficiency depend on it.

Introduction

Inventory accuracy is a measure for calculating the difference between recorded stock and actual inventory. For example, a polymer company might have 100 units of resin products in their stockroom out of which only 75 units are recorded in their inventory management system. This means that their inventory accuracy is 75%.

Every step of the production process, starting from planning and stocking raw materials to the customers buying the finished goods and their satisfaction, is dependent on inventory accuracy.

Inaccuracy in inventory management leads to financial loss because of overstocking and stockouts. To ensure optimal efficiency in the process of production in the resin industry, it is necessary to improve inventory accuracy.

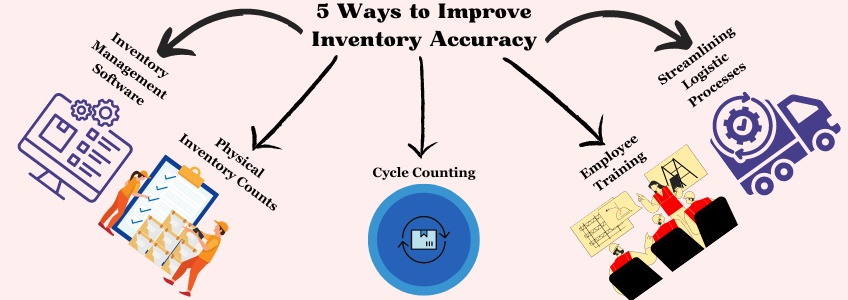

5 Ways to Improve Inventory Accuracy in the Resin Industry

The Resin Industry must implement these five basic strategies to improve its inventory accuracy.

1. Conducting physical Inventory Counts regularly

Regular physical inventory counts are a necessary aspect of inventory management. It helps to keep track of the actual stock levels, identify any variations and work on those.

The resin industry should determine the frequency of conducting these physical inventory counts based upon their product value, risk of inventory shrinkage and inventory turnover.

The resin industry should adopt a standardized counting process to ensure reliability and consistency, even while dealing with discrepancies. Modern technology like Radio Frequency Identification (RFID) can be implemented to optimize the counting process.

2. Adopting an Inventory Management Software

Inventory Management software has the capability of improving inventory accuracy by providing real-time insights into stock levels, generating accurate reports and carrying out automated processes.

The resin industry should employ inventory management software that is collaborative and offers advanced features like barcode scanning and lot tracking.

The software to be implemented should also be customizable to meet the specific needs of the resin industry.

The industry must train its staff and employees against any technical issues that might hinder the implementation of the inventory management software.

3. Implementing Cycle Counting

The process of counting certain items periodically instead of carrying out the physical count at once is known as cycle counting. It reduces the risk of errors as variations and discrepancies are identified more frequently.

Prioritizing the products to be included in for cycle should be based on their criticality, value and history of discrepancy. The resin industry should also set up a fixed schedule to conduct the cycle counting.

This ensures that all the products are counted within a specific timeline. The data obtained from these cycle counts, help the resin manufacturers to track trends and recognise the areas that need improvement.

4. Training the Employees

The manufacturers can also include improvement of inventory accuracy as a criterion for getting future incentives for the employees. Employees should be provided with comprehensive training programmes.

These topics must include topics like inventory counting, cycle counting, use of inventory management software, etc.

The resin manufacturers must ensure that their employees are properly trained in inventory management procedures. This will help them get a better understanding of the importance of improving inventory accuracy.

Opportunities for ongoing development should also be provided for the employees to keep them updated on the polymer market trends and best practices.

5. Streamlining the logistic processes

Logistics includes both the receiving and the shipping procedures. Only with an efficient transportation process can the inventory records be accurate.

The resin manufacturers should adopt a rigorous verification process while receiving shipments. They should verify the purchase orders with the quality and quantity of the products received.

The company must also ensure timely and accurate documentation of products received as well as shipped, throughout the supply chain.

The use of technology like bar code scanning can also optimize inventory accuracy and reduce errors related to receiving and shipping goods.

Conclusion

Inventory accuracy is one of the foundational bases upon which the efficiency and profitability of the company depend. Following the above-mentioned 5 steps can significantly improve the inventory accuracy of the resin industry.

This will ensure not only financial accuracy and operational excellence but also facilitate data-driven decision-making and improve customer satisfaction.

If you are interested to achieve similar success stories, write to us!