The Lean tool Kanban is one of the most important aspects of any organization. One should be well-versed in calculating the number of Kanban cards. Kanban can be broadly divided into 2 types – i.e., Transport Kanban and Production Kanban. Additionally, these categories have 2 further subdivisions each. Transport Kanban branches out into Supplier Kanban and Withdrawal Kanban, and Production Kanban diversifies into Product-ordering Kanban and Signal Kanban. Therefore, there are a total of 4 types of Kanban that we’ll be looking into here. Find below a tabular representation of these 4 types for easier comprehension:

Table: Different types of Kanban

Concerning Kanban, there are 2 main activities in manufacturing and services. These are to move (send or email in services) and produce (transact in services). Consequently, we need to address the following questions:

- What, where, when, and how much to move? – Transport Kanban addresses these questions.

- What, where, when, and how much to produce? – Production Kanban address these questions.

Kanban helps regulate the material flow using cards as a signal to either produce or move. Subsequently, cards carry the information necessary to trigger work.

Let’s take a look at the 4 types of Kanban:

1. Transport Kanban

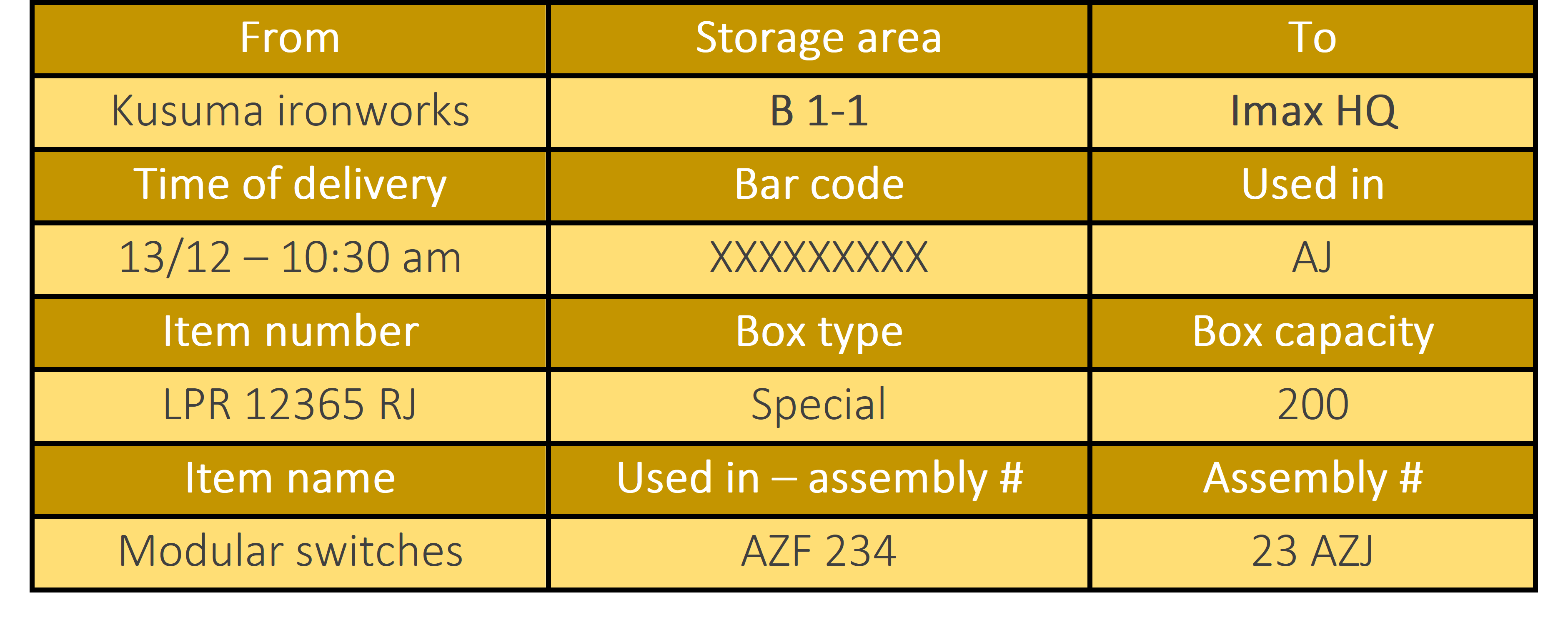

This is the format and an example of a Transport Kanban:

a) Supplier Kanban or Parts-ordering Kanban

Find below the format and example of a Supplier/ Parts-ordering Kanban:

Note: Modify the contents of these cards to suit your business and products.

b) Withdrawal or In-factory Kanban

Here is the format and an accompanying example of a Withdrawal or In-factory Kanban:

2. Production Kanban

Find below the details about the formatting for the 2 kinds of Production Kanban, and associated examples:

a) Product-ordering Kanban

The following is the layout as well as an example of a Product-ordering Kanban:

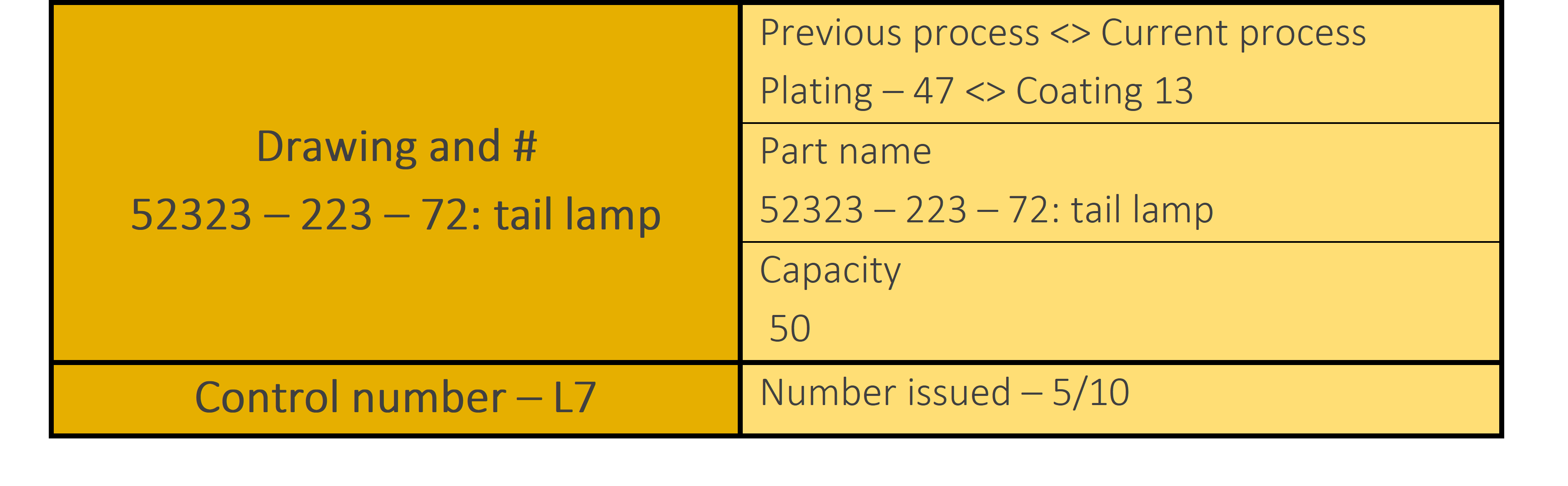

b) Signal Kanban

A Signal Kanban is usually triangular. It is used to ‘signal’ production when the order point is reached. They are hung above the line next to the signs that indicate the product being produced in that line of the cell. Here’s what a Signal Kanban format looks like:

Figure: Signal Kanban

In case you’d like to have a deeper understanding of Kanban, make sure you check out the most frequently asked questions surrounding its implementation!